Choosing the Perfect Prefabricated Steel Equestrian Building

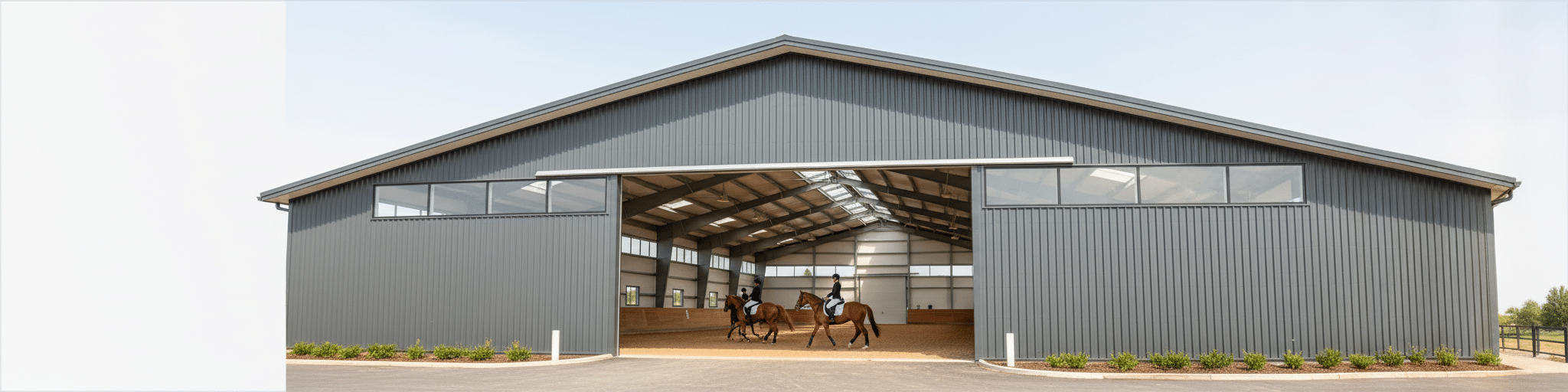

Selecting the right structure for your equestrian facility represents one of the most critical decisions you'll make as a horse owner or stable operator. Whether you're establishing a private barn for personal use, expanding a boarding facility, or creating a professional training arena, the building you choose directly impacts the safety, comfort, and performance of both horses and riders.

Prefabricated steel buildings have revolutionized equestrian construction, offering solutions that address the unique challenges these facilities face daily. From withstanding powerful kicks and constant moisture exposure to providing expansive clear-span spaces for unobstructed riding, modern steel structures deliver capabilities that traditional building methods struggle to match.

This comprehensive guide walks you through every aspect of selecting and implementing a prefabricated steel equestrian building. You'll discover the distinct advantages these structures offer, learn how to assess your specific facility requirements, and understand the essential features that ensure long-term success. We'll explore customization options that enhance functionality, guide you through selecting the right manufacturer, and detail the installation process from site preparation to final inspection.

At National Steel Buildings Corp, we understand that every equestrian operation has unique needs. Our experience in designing and constructing these specialized facilities helps ensure your investment delivers lasting value and exceptional performance.

Advantages of Prefabricated Steel for Equestrian Applications

How can prefabricated steel transform your equestrian facility into a safer, more efficient operation?

Durability and Weather Resistance in Demanding Environments

When you're managing an equestrian facility, durability isn't just a nice-to-have—it's essential. Prefabricated steel buildings stand up to the unique demands of horse facilities in ways traditional construction simply can't match. Think about your daily routine: pressure washing stalls, horses kicking walls, equipment bumping into surfaces. Steel construction takes all of this in stride.

The secret lies in advanced galvanization and protective coatings that create a barrier against moisture and corrosion. Unlike wood that absorbs water and harbors bacteria, steel panels maintain their integrity year after year. Heavy-gauge channels and double-thickness galvanized bottom rails form a weatherproof envelope that keeps your investment protected. This means you're spending less time on repairs and more time focusing on what matters—your horses and your business.

Clear-Span Design: Maximizing Usable Space for Riding and Training

Picture an arena where nothing stands between you and perfect riding conditions—no posts to navigate around, no low-hanging trusses to worry about. That's the power of clear-span steel construction. By using engineered I-beam frames with quarter-inch thick plate steel, we create expansive open spaces that give horses and riders complete freedom of movement.

This design philosophy goes beyond just creating space. It's about safety and efficiency. Without interior columns, there's nothing for a spooked horse to collide with, and your arena maintenance becomes remarkably simple—equipment can move freely from wall to wall. The engineering behind these structures allows for impressive spans while maintaining absolute stability. As we'll explore in later sections on facility requirements and customization, this flexibility lets you design spaces that adapt to your specific discipline, whether that's dressage, jumping, or therapeutic riding programs.

Cost-Effectiveness: Initial Investment vs. Lifetime Value

Let's talk honestly about investment. Yes, a steel building costs about 15% more upfront than a traditional pole barn. But here's what that extra investment gets you: insurance premiums that are typically 30% lower thanks to steel's fire-resistant properties, and virtually elimination of the constant maintenance that wooden structures demand.

Think long-term value. Our prefabricated steel equestrian buildings deliver returns through reduced operating costs, minimal maintenance requirements, and exceptional longevity. When you factor in the savings from avoided repairs, lower insurance premiums, and the building's 50+ year lifespan, that initial investment premium typically pays for itself within the first five years of ownership.

Speed of Construction and Minimal Site Disruption

Time is money in the equestrian business, and traditional construction can mean months of disruption to your operations. Prefabricated steel changes that equation entirely. While site preparation proceeds on your property, your building components are being precision-manufactured in a controlled factory environment. This parallel process can cut months off your project timeline.

Here's what this means for your facility: less noise, minimal dust, and dramatically reduced equipment traffic on your property. If you're running lessons or boarding operations, you can maintain near-normal activities throughout most of the construction process. The controlled manufacturing environment also eliminates weather delays and labor uncertainties that typically derail construction schedules. You get a predictable timeline you can actually count on—essential when you're planning around show seasons or have boarding contracts to fulfill. It's construction that works around your business, not the other way around.

Assessing Your Equestrian Facility Requirements

Proper facility planning ensures decades of efficient operations and satisfied equine residents.

Determining Optimal Size: Horse Space Requirements and Industry Standards

When determining optimal dimensions for your equestrian facility, industry standards provide valuable guidance. Standard horse stalls measure 12x12 feet for average-sized horses, while larger breeds like warmbloods and drafts benefit from 14x14 feet or at least 12x14 feet to ensure comfortable movement. A small horse barn requires a minimum of 300 square feet to properly house two horses, with most efficient designs featuring a center aisle configuration.

At National Steel Buildings Corp, we understand that proper aisle width is crucial for both safety and functionality. We recommend at least 12-foot wide aisles, though 14-foot aisleways provide superior traffic flow and enhance natural ventilation throughout your facility. Ceiling height plays an equally important role - while 10 feet represents the minimum requirement, taller ceiling heights significantly improve air circulation and create a more comfortable environment for both horses and handlers.

Though upgrading from standard dimensions typically adds about 12% to initial construction costs, our experience shows these investments pay dividends through improved horse health, reduced veterinary expenses, and enhanced facility functionality. Essential safety features include doorway openings of at least 7 feet high and 42-45 inches wide, ensuring safe passage while accommodating equipment movement.

Planning for Multi-Functional Use: Arenas, Stables, and Support Areas

Creating an efficient multi-functional equestrian facility requires thoughtful planning of operational areas. Through our years of designing steel buildings for equestrian applications, we've learned that strategic placement of support spaces can dramatically improve daily operations. Feed rooms should provide convenient access while maintaining security - properly positioned with reinforced doors to prevent unauthorized equine visitors.

Space allocation varies with facility size: smaller operations with 4-12 stalls typically require 10'x10' to 12'x12' for tack storage, while larger facilities housing 8-20 horses benefit from 10'x20' to 12'x24' dedicated storage areas. Wash bay placement near tack rooms streamlines post-ride routines (detailed drainage requirements are covered in our Flooring and Footing section).

Our prefabricated steel construction excels at creating versatile spaces that adapt to changing needs. The clear-span capabilities we discussed earlier enable seamless transitions between riding arena and event space, or stable and equipment storage. This flexibility proves invaluable as your operation evolves, allowing you to reconfigure spaces without structural limitations.

Climate Considerations: Insulation, Ventilation, and Environmental Control

Climate control represents a critical consideration when planning your steel equestrian facility. Our prefabricated steel buildings accommodate modern insulation systems that effectively regulate internal temperatures while significantly reducing long-term energy costs. The building envelope design requires careful attention - proper insulation not only maintains comfortable conditions year-round but also prevents moisture buildup that could compromise horse health and structural integrity.

A key advantage of steel construction is the material's inert nature - unlike traditional wooden structures, steel doesn't emit harmful vapors or harbor moisture that can affect air quality. This characteristic works in concert with properly designed ventilation systems (detailed specifications for ventilation are covered in our Essential Features section).

Temperature regulation proves especially crucial in enclosed arenas. Our engineering team can design customized insulation packages that reduce energy costs by up to 30% while maintaining stable indoor conditions essential for horse comfort and performance. By combining strategic insulation placement with appropriate ventilation design, we create controlled environments that protect equine health while maximizing your facility's operational efficiency and minimizing ongoing utility expenses.

Future-Proofing: Designing for Potential Expansion

Future-proofing your equestrian facility requires strategic planning that anticipates growth. At National Steel Buildings Corp, we design with expansion in mind, utilizing modular construction principles that allow your facility to evolve alongside your operation. Our prefabricated steel components enable seamless additions without compromising structural integrity - initial building widths can expand through engineered connections as your needs grow.

The modular approach we employ significantly reduces future construction disruption. Components arrive pre-manufactured for rapid assembly, dramatically shortening construction timelines compared to traditional methods. This means minimal disruption to your ongoing operations when the time comes to expand.

Strategic space planning should incorporate flexibility from the start. When designing smaller facilities, we recommend allocating versatile 10'x10' to 12'x12' spaces that can adapt between tack storage, grooming stations, or additional stalls as your operation evolves. This built-in flexibility protects your initial investment while providing clear pathways for growth.

Our design team can help you select layout configurations that facilitate future expansion. U-shaped designs have proven particularly effective for growing operations - they create protected central courtyards while establishing natural separations between functional zones. This thoughtful approach enables expansion without disrupting existing traffic patterns or compromising biosecurity protocols.

Essential Structural and Design Features

Steel buildings engineered for equestrian use deliver unmatched structural integrity and safety.

Engineering Standards for Equestrian Applications

At National Steel Buildings Corp, we understand that prefabricated steel equestrian buildings demand the highest engineering standards to ensure both safety and structural integrity. Our designs incorporate specific load calculations that account for the unique stresses these facilities encounter - from the dynamic loads of cantering horses to the static weight of stored hay and equipment.

Each building undergoes rigorous engineering review to meet or exceed International Building Code requirements while addressing equestrian-specific needs. This includes calculating for lateral forces from horse impacts, ensuring adequate structural redundancy, and designing connection points that maintain integrity under repeated stress. Our engineering team specializes in creating structures that balance optimal strength-to-weight ratios with the practical needs of daily equestrian operations.

Roof Systems: Height, Pitch, and Clearance Considerations

Selecting the right roof system balances functionality with aesthetics while meeting your facility's specific needs. A 4:12 pitch - rising 4 inches for every 12 inches of horizontal span - delivers optimal water drainage while maintaining an attractive profile that complements your property. For indoor arenas where maximizing usable space is critical, lower pitches like 1:12 or 2:12 minimize the air volume overhead, significantly reducing your heating and cooling costs while simplifying maintenance access.

Our engineering team carefully designs each roof system to account for your local weather conditions, ensuring proper snow and rain shedding while maintaining structural integrity during severe winds. As discussed in earlier sections, clear-span designs accommodate the specific height requirements for various equestrian activities, from basic riding to advanced jump training.

For facilities anticipating growth, our modular roof designs enable seamless future expansions without compromising your building's weather envelope. This forward-thinking approach allows your structure to grow from an initial 60-foot width up to 200 feet through engineered connections, protecting your investment while accommodating your evolving business needs.

Wall Systems and Exterior Cladding Options

Today's metal buildings provide exceptional flexibility in wall systems and exterior cladding options to match your facility's aesthetic vision. Since structural integrity comes from the steel framing and fasteners rather than exterior panels, you have diverse material choices that extend far beyond traditional metal siding.

Popular cladding materials include stainless steel for excellent rust resistance and contemporary aesthetics, and galvanized steel with protective zinc coating for cost-effective durability. To enhance visual appeal and blend with existing architecture, we can incorporate brick, stucco, faux stone, or wood siding that maintains your property's cohesive look.

Aluminum cladding systems have become increasingly popular for equestrian facilities due to their lightweight nature and superior corrosion resistance - particularly valuable in humid environments or locations with frequent washing requirements. The selection among cladding system types - standing seam, snaplock, interlocking, or flatlock panels - depends on your specific weather exposure, maintenance preferences, and design goals.

Installation methods vary by system type, with some offering rapid snap-together assembly while others require specialized techniques to ensure complete weatherproofing. When selecting exterior finishes, we consider durability against your local environmental conditions, thermal expansion properties, and compatibility with your building's insulation and ventilation systems - ensuring a cohesive solution that performs beautifully for decades.

Foundation Requirements for Stability and Safety

A properly engineered foundation forms the cornerstone of any successful prefabricated steel equestrian building. We begin every project with thorough geotechnical testing to analyze your site's soil load-bearing capacity and drainage characteristics. This critical assessment guides our foundation design, accounting for soil composition, water tables, and potential natural hazards while incorporating appropriate reinforcement methods.

Concrete slabs remain the most common and cost-effective foundation option for level sites. However, for properties with uneven terrain, pier systems offer superior performance by transferring loads to deeper, stable soil layers. In colder climates, we ensure foundations extend below the frost line to prevent shifting from freeze-thaw cycles - a detail that protects your investment for decades.

Proper drainage integration proves essential for long-term stability. We incorporate comprehensive solutions including French drains and strategic grading to direct water away from your structure. Steel reinforcements such as rebar and wire mesh enhance the foundation's ability to withstand heavy loads and resist cracking - particularly crucial for large clear-span equestrian facilities where load distribution becomes more complex.

Our professional engineers optimize each foundation design to effectively distribute loads while resisting environmental stresses unique to your location. This often includes recommending material enhancements like reinforced concrete specifications or additional anchor bolts that ensure your building maintains structural integrity throughout its service life.

Customization Options for Equestrian Functionality

Customized features transform basic structures into exceptional equestrian facilities.

Stall Design and Interior Configurations

Effective stall design starts with Dutch doors that balance safety and comfort - the split opening allows horses to look outside while maintaining secure containment when needed. Traditional layouts feature a central aisle with stalls on both sides, promoting efficient horse management and easy access. The design should incorporate proper ventilation through strategic door and window placement to maintain healthy airflow.

For optimal functionality, stalls require nonslip flooring, durable partitions, and automated features like waterers and hay feeders to enhance horse comfort and simplify care routines. As discussed in the Clear-Span Design section, our steel construction enables these expansive layouts without interior columns, maximizing usable space for your equestrian operations.

The layout should minimize cross-traffic between different functional areas to reduce horse stress, with dedicated zones for grooming, veterinary care, and farrier work. Strategic placement of overhangs and paddock shelters gives horses options for shade and weather protection while maintaining proper air circulation throughout the facility. Our prefabricated systems accommodate all these design elements while maintaining the structural integrity essential for long-term performance.

Specialized Flooring and Footing Materials

Specialized flooring and footing materials in equestrian buildings require careful consideration to ensure horse safety and comfort. As detailed in the Foundation Requirements section, proper drainage solutions and geotechnical testing form the basis of any successful equestrian facility.

For optimal functionality, stalls demand nonslip flooring that can withstand daily cleaning and animal impacts without deterioration. The choice of footing material depends on your specific equestrian activities - from rubber mats for general stabling to specialized arena surfaces for training and competition. Steel buildings provide the structural integrity needed to support various flooring options, whether you're installing concrete aisles with textured finishes or cushioned stall mats over compacted base materials.

The beauty of prefabricated steel construction lies in its adaptability to different flooring systems. Whether you need drainage channels for wash bays or level surfaces for dressage arenas, the steel framework accommodates these specialized requirements while maintaining the building's structural integrity.

Ventilation Systems for Horse Health and Comfort

Proper ventilation systems must provide both air exchange and distribution to maintain horse health. Air exchange replaces stale air with fresh air, while distribution ensures fresh air reaches throughout the stable. Building on the climate control concepts discussed earlier, effective ventilation requires 4-8 air changes per hour to control mold, condensation, moisture, and ammonia.

Natural ventilation, driven by wind and thermal buoyancy, requires strategic placement of openings along sidewalls and the ridge. Each stall needs at least 1 square foot of permanent opening for year-round fresh air access, ideally positioned at the eave where sidewall meets roof.

Ventilation requirements vary by season:

- Cold weather: 25 cubic feet per minute (cfm) per 1,000 pounds of horse to control moisture

- Mild weather: 100 cfm for comfortable conditions

- Hot weather: 200-350 cfm for optimal cooling

Steel buildings excel at incorporating both natural and mechanical ventilation systems. The structural design allows for ridge vents, cupolas, and strategically placed wall openings without compromising building integrity. For facilities with unique challenges, mechanical ventilation through fans and ducts can supplement natural airflow. The goal is maintaining temperatures no more than 5-10°F warmer than outside while preventing condensation - a balance that steel buildings achieve through their adaptable design and optional insulation systems.

Lighting Solutions for Various Equestrian Activities

Proper lighting is essential for both safety and functionality in equestrian facilities. Indoor arenas require higher illumination levels than outdoor spaces, with requirements varying significantly by discipline and competition level. Understanding these needs helps ensure your facility supports both horse welfare and rider performance.

Indoor lighting typically ranges from 18.5 footcandles for dressage training to 65 footcandles for top-level show jumping competitions. Steel buildings provide ideal mounting points for fixtures, with roof supports at appropriate heights (typically 15'6") ensuring even light distribution. The clear-span design eliminates shadows from interior columns, creating consistent illumination across the riding surface.

LED lighting systems have revolutionized equestrian facilities, offering:

- Targeted illumination with minimal shadows

- Energy cost reductions up to 60%

- Minimal light spillage to neighboring properties

- Long lifespan reducing maintenance needs

Since horses are dichromatic (seeing primarily blues and yellows) and struggle with quick light-to-dark transitions, proper lighting design must account for their unique vision. Professional facilities typically require:

- 700 lux for high-level competition

- 300 lux for standard training

- 400-500 lux for jump training

- Color temperatures between 4000K-5000K for natural visibility

The structural flexibility of steel buildings allows for various lighting configurations, from simple training setups to professional competition standards, all while maintaining the building's clean aesthetic and functional design.

Integrated Storage and Support Facilities

Integrated storage and support facilities are essential components of modern equestrian buildings. As outlined in the Multi-Functional Use Planning section, steel structures enable customizable configurations that combine stall areas with dedicated spaces for tack rooms, grooming bays, and feed storage - all designed to maximize operational efficiency.

The flexibility of prefabricated steel construction allows facilities to seamlessly incorporate:

- Temperature-controlled tack rooms protecting valuable equipment

- Secure feed storage areas with proper ventilation

- Grooming bays with adequate lighting and drainage

- Office spaces for facility management

- Locker rooms for staff and riders

- Veterinary examination areas

For optimal functionality, wash bays should be positioned near tack rooms for convenience, incorporating proper drainage systems with 2% grade slopes and non-slip flooring. The strategic placement of these support areas maintains efficient workflow patterns throughout the facility while naturally separating different functional zones.

This integrated approach transforms your equestrian building from a simple shelter into a comprehensive facility that supports all aspects of horse care and management. The modular nature of steel construction means these spaces can be reconfigured or expanded as your operation grows, protecting your investment while adapting to your evolving needs.

Selecting the Right Manufacturer and Building Kit

Choosing an experienced manufacturer ensures your equestrian facility meets the highest standards.

Evaluating Manufacturer Experience with Equestrian Projects

When evaluating manufacturers for prefabricated steel equestrian buildings, prioritize those with extensive experience in arena construction across different disciplines. Look for manufacturers who demonstrate understanding of specific requirements for various riding styles - from dressage to jumping arenas - as these specialized needs impact critical design elements like eave heights and clearances. The minimum eave height requirements vary significantly by discipline, with dressage arenas needing at least 16 feet and hunter-jumper facilities requiring 18-20 feet depending on building size. Beyond technical specifications, assess manufacturers' ability to handle comprehensive project management, including permitting navigation and code compliance. Leading manufacturers maintain relationships with nationwide networks of vendors and steel plants to meet construction timelines while ensuring quality standards. They should also demonstrate capability in coordinating essential components like lighting, drainage systems, and foundation work, though specialized elements like arena footing typically require separate contractors.

Understanding Building Kit Components and What's Included

Standard prefabricated steel building kits include essential structural components: primary and secondary framing members, roof and wall panels, fasteners, trim packages, and detailed assembly drawings. Quality manufacturers provide comprehensive documentation including engineered plans stamped by licensed professionals, assembly instructions with step-by-step guidance, and material lists for accurate inventory management.

However, it's equally important to understand what's typically not included: concrete foundations and anchor bolts, insulation and vapor barriers, doors and windows beyond basic personnel entries, electrical and plumbing systems, and interior finishing materials. These elements often require local sourcing to meet regional codes and climate requirements.

At National Steel Buildings Corp, we help clients navigate these distinctions, ensuring you budget appropriately for a complete facility. Our kits can be customized to include additional components based on your specific needs, from specialized ventilation systems to integrated door and window packages designed for equestrian applications.

Warranty Considerations and Long-term Support

Prefabricated steel buildings typically come with multi-tiered warranty protection that safeguards different components. Quality manufacturers offer 40-70 year structural warranties when buildings are properly maintained, significantly outlasting traditional wood or concrete structures. Standard warranty packages include 20-year rust-through protection, 10-year panel coverage, and 1-year workmanship guarantees. However, warranties have important limitations - they're non-transferrable between owners and don't cover damage from natural disasters or modifications made after installation. For coastal facilities, warranty terms may be adjusted due to increased corrosion risks from humidity and salt exposure. To maintain warranty coverage, buildings require semi-annual inspections - typically a quick check in spring and thorough evaluation in fall to prepare for winter conditions. Reputable manufacturers provide detailed preventative maintenance manuals outlining inspection procedures, cleaning protocols, and repair guidelines that must be followed to preserve warranty validity. This long-term support demonstrates a manufacturer's confidence in their product and commitment to your investment.

Building Codes, Permits, and Compliance Issues

Navigating building codes and permits for prefabricated steel equestrian buildings requires understanding multiple approval layers. The process starts with obtaining standard building permits that authorize construction and verify structural elements, foundation work, and overall building envelope. Projects also need zoning permits to ensure compliance with local land use regulations, whether commercial, agricultural, or residential. Site development permits become necessary when significant landscape changes are involved, covering grading, drainage modifications, and utility installations. The International Building Code (IBC) serves as the foundation for structural requirements, addressing load-bearing calculations, wind resistance, seismic considerations, and snow load specifications based on your geographic location. Steel buildings must demonstrate ability to withstand environmental stresses through detailed engineering drawings that show structural specifications, foundation details, and material specifications - elements we covered thoroughly in our structural features section. The approval process typically involves multiple inspections, including foundation, framing, electrical rough-in, mechanical systems, and final occupancy approval. To ensure long-term compliance, proper documentation protects insurance coverage and property value, as insurance companies may deny claims for structures built without correct permits or that fail to meet applicable building codes. A knowledgeable manufacturer will guide you through this complex process, helping navigate local requirements while ensuring your facility meets all necessary standards.

Installation Process and Timeline

Professional installation ensures your equestrian facility performs flawlessly for decades.

Site Preparation Requirements

Successful installation begins with meticulous site evaluation, focusing on terrain that provides both stability and accessibility for construction equipment. The preparation process involves clearing all vegetation, debris, and existing structures to establish a clean foundation for your new equestrian facility. Understanding the soil's characteristics through professional testing reveals critical information about load-bearing capacity and drainage requirements - insights that guide decisions about necessary ground improvements such as compaction or gravel base installation.

As discussed in the Foundation Requirements section, proper foundation preparation forms the cornerstone of structural integrity. When opting for a concrete pad foundation, patience during the curing process proves essential. This chemical transformation strengthens the concrete through crystalline development, and rushing this phase invites costly problems like cracking or structural failure. The site's drainage system, incorporating elements like French drains and strategic grading, protects your investment by directing water away from the building's base.

Professional vs. DIY Installation Considerations

Choosing between professional and DIY installation involves weighing immediate cost savings against long-term value and safety. While handling installation yourself might reduce initial expenses by approximately 5%, this approach works best for those with solid construction experience and reliable assistance. The complexity of equestrian facilities - where proper assembly directly impacts both horse safety and structural longevity - often makes professional installation the wiser investment.

Experienced installation crews bring specialized knowledge that transforms potential challenges into smooth solutions. They understand the unique requirements of equestrian structures, from managing heavy clear-span components to ensuring precise alignment of stall systems. Professional teams also recognize critical details that inexperienced installers might overlook, such as proper bolt tensioning patterns and load distribution principles that safeguard your facility's integrity.

A hybrid approach offers an intelligent compromise for budget-conscious owners. By managing site preparation and finishing touches yourself while entrusting the structural assembly to professionals, you maintain quality control over critical safety elements while still participating in your project's creation. This balanced strategy ensures your equestrian facility meets the highest standards while respecting your budget constraints.

Typical Construction Timeline for Prefab Steel Equestrian Buildings

Your prefabricated steel equestrian building timeline depends on several controllable and environmental factors. Once materials arrive on-site, smaller facilities featuring standard configurations typically achieve weathertight status within 3-5 days. Medium to large commercial operations spanning up to 100,000 square feet generally require 2-4 weeks for complete assembly, while highly customized designs with specialized features may extend to 8-12 weeks.

Understanding timeline variables helps set realistic expectations for your project. Clear-span designs exceeding 80 feet require additional assembly time due to the heavier structural components involved. Weather plays an unavoidable role - winter conditions and severe storms can affect both material delivery and safe working conditions on-site. However, working with experienced crews familiar with equestrian facility requirements typically results in faster completion times and fewer weather-related delays.

The manufacturing lead time before delivery represents another crucial consideration. Standard building configurations often ship within 2-4 weeks of order finalization, while custom designs may require 6-10 weeks for engineering and production. Planning your project timeline should account for these manufacturing windows plus site preparation, actual construction, and final inspections.

Post-Installation Inspections and Quality Assurance

Thorough post-installation inspections safeguard your investment by verifying that every component meets stringent safety standards. The inspection process methodically examines critical connection points, ensuring each structural column features proper anchoring and that frame assemblies maintain required bolt patterns for optimal load distribution. For concrete foundations, inspectors confirm complete curing has occurred before approving the structure for use - a crucial step that prevents costly foundation failures.

Quality assurance encompasses multiple inspection phases that protect both immediate functionality and long-term performance. Professional inspectors evaluate the foundation integrity, structural framing alignment, and integration of all building systems. They verify compliance with applicable building codes while documenting conditions that support your warranty coverage - essential protection for your significant investment.

Maintaining your equestrian facility's value requires ongoing vigilance through scheduled inspections. As detailed in the warranty section, semi-annual evaluations help identify minor issues before they escalate into major repairs. Spring inspections focus on winter damage assessment, while comprehensive fall reviews prepare your facility for harsh weather ahead. This proactive maintenance approach, combined with adherence to manufacturer guidelines, ensures your steel building continues providing safe, reliable shelter for your equestrian operations for decades to come.

The information presented in this guide is based on industry standards, building codes, and decades of experience in steel construction for equestrian facilities. Key sources include:

- International Building Code (IBC) - Structural requirements, load calculations, and safety standards for steel buildings

- OSHA Construction Standards - Safety requirements for steel erection and structural assembly (29 CFR 1926.758)

- American Institute of Steel Construction (AISC) - Design specifications for structural steel buildings

- Metal Building Manufacturers Association (MBMA) - Industry standards for pre-engineered metal buildings

- American Society of Agricultural and Biological Engineers (ASABE) - Standards for agricultural building ventilation and environmental control

- Penn State Extension Service - Research-based guidelines for equestrian facility design and horse health requirements

- Illuminating Engineering Society (IES) - Lighting standards for sports facilities and equestrian arenas

At National Steel Buildings Corp, we combine these industry standards with our extensive experience in designing and constructing equestrian facilities. Our engineering team stays current with evolving codes and best practices to deliver buildings that exceed expectations for safety, functionality, and longevity.

For specific technical specifications or to discuss how our prefabricated steel buildings can meet your equestrian facility needs, contact our design team at National Steel Buildings Corp.