Maximizing Energy Efficiency in Metal Buildings for Long-Term Savings

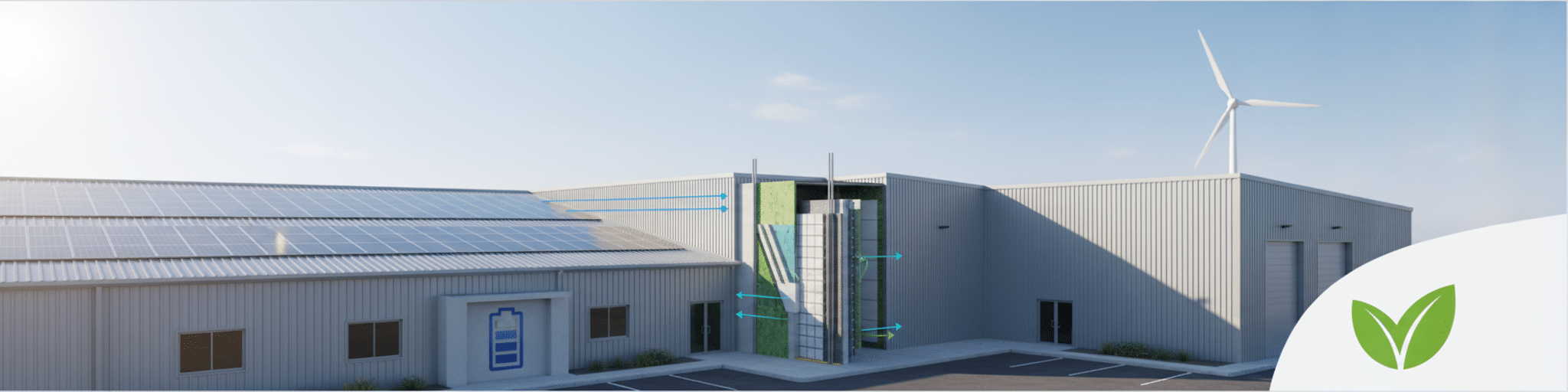

This comprehensive guide explores strategies for maximizing energy efficiency in metal buildings, from advanced insulation systems to smart building technologies. Learn how proper design, construction, and operational practices can reduce energy costs by up to 30% while extending building lifespan and qualifying for valuable tax incentives.

Introduction

How can energy-efficient design transform your metal building's long-term operational costs?

The Rising Energy Costs in Commercial Construction

The buildings sector currently accounts for over one-third of global energy consumption and emissions, making energy costs a critical concern for commercial construction. Recent market shifts have intensified these challenges, with steel prices soaring due to new tariffs and supply chain constraints leading to notable price increases across the industry. The impact extends beyond raw materials - energy used for heating, cooling, and lighting in commercial buildings shapes long-term operational expenses, with design and purchasing decisions made today affecting energy use for decades to come. Metal building manufacturers are now navigating a complex pricing environment, as elevated fuel costs, transportation fees, and labor expenses create additional pressures throughout the supply chain. This evolving landscape makes energy efficiency not just important, but essential for long-term success. When properly designed and constructed, metal buildings can deliver substantial reductions in operational costs compared to traditional construction methods.

Metal Buildings: Efficiency Potential and Challenges

Metal buildings offer significant efficiency potential while presenting unique challenges that must be addressed. These structures account for nearly 30% of low-rise commercial construction in the U.S. and must meet the same stringent energy requirements as traditional buildings. A key consideration is thermal bridging, which we'll explore in detail later in this guide. However, metal buildings have inherent advantages - their deeper structural members (6-12 inches) create more space for insulation, and their typical 5-foot member spacing naturally reduces thermal bridge points compared to traditional construction methods. The adaptability of steel allows for seamless integration of high-performance insulation solutions. Modern approaches include insulated metal panels (IMPs) that combine structural support with superior thermal performance, rigid foam boards that maintain consistent R-values, and reflective barriers that address radiant heat transfer. These systems work together to create highly efficient thermal envelopes that rival or exceed traditional construction methods.

The Long-Term Financial Impact of Energy-Efficient Design

Energy-efficient metal buildings deliver compelling financial returns through multiple pathways. These structures can significantly reduce operational energy costs through features like advanced insulation systems and smart building controls. The payback period for energy efficiency investments typically ranges from 3-5 years, after which the savings contribute directly to your bottom line. Beyond direct energy savings, efficient metal buildings command higher property values and rental premiums, particularly in sectors where companies prioritize sustainable spaces. The financial advantages compound over time - metal structures require minimal maintenance while offering superior durability against environmental factors, translating to reduced repair and replacement costs throughout the building lifecycle. As we'll discuss in detail in the Economic Analysis section, when combined with available tax incentives and financing options for energy-efficient construction, the total return on investment makes these buildings increasingly attractive for forward-thinking property owners and developers.

Understanding the Energy Dynamics of Metal Buildings

Metal buildings can compensate for steel's conductivity through intelligent design and insulation strategies.

Thermal Properties and Challenges Unique to Metal Construction

Understanding the thermal dynamics of metal buildings is essential for maximizing their energy efficiency potential. Steel's high conductivity presents both challenges and opportunities that experienced builders know how to leverage. The primary consideration is managing thermal bridging - the phenomenon where heat transfers through metal components connecting interior and exterior surfaces.

What makes metal buildings unique is their ability to compensate for steel's conductivity through intelligent design. With structural columns spaced up to 25 feet apart (compared to wood's typical 16-inch stud spacing), we create fewer thermal bridge points while maintaining exceptional strength [8]. These wider spans also allow for deeper wall cavities - often 9 inches or more versus wood framing's 3.5 inches - providing ample space for comprehensive insulation systems [8].

Without proper thermal management, the consequences extend beyond energy waste. Building owners may face escalating HVAC costs, condensation issues that threaten structural integrity, and potential moisture problems that compromise indoor air quality [9]. That's why specialized insulation approaches are critical. Modern solutions, including advanced insulated metal panels and continuous insulation systems, effectively address these challenges while maintaining the structural advantages of steel construction.

Critical Energy Loss Points in Standard Metal Buildings

Identifying and addressing critical energy loss points is fundamental to achieving optimal performance in metal buildings. As discussed above, thermal bridging remains the primary concern, particularly at structural connection points like rafters, purlins, and girts [11]. These steel components can create direct pathways for heat transfer if not properly managed.

Beyond the main structural elements, several other vulnerable areas demand attention. Building envelope connections - particularly wall-to-roof junctions and exterior cladding attachments - represent common weak points where insulation continuity breaks down [11]. Utility penetrations for electrical, plumbing, and HVAC systems also require careful sealing to prevent air infiltration and energy loss.

The solution lies in comprehensive thermal management strategies. Thermal spacer blocks installed between metal components create essential breaks in conductive pathways. When combined with continuous insulation systems, these measures prevent the cascade of problems that poor thermal control can trigger - from escalating energy costs to moisture accumulation that causes interior wall discoloration and compromised insulation performance [8]. Each connection point, penetration, and transition requires thoughtful detailing to maintain the integrity of the building's thermal envelope.

How Energy Efficiency Directly Impacts Building Longevity

The relationship between energy efficiency and building longevity creates a powerful synergy that savvy building owners leverage for long-term value. When metal buildings are properly designed with energy efficiency in mind, they deliver benefits that compound over decades of service life.

Efficient thermal management protects the structural integrity of steel components in multiple ways. Proper insulation systems prevent the condensation that can lead to corrosion, extending the life of structural members far beyond their already impressive durability [12]. By maintaining consistent interior temperatures and minimizing thermal stress on building materials, high-performance insulation systems serve as guardians of your investment [13].

Metal buildings already excel at resisting environmental challenges - from high winds and heavy snow loads to seismic activity. Energy-efficient design enhances this natural resilience by reducing the thermal cycling that can stress connections and fasteners over time [12]. The result is a building that not only performs better day-to-day but maintains that performance level for generations.

This integrated approach creates a virtuous cycle: reduced thermal bridging prevents moisture accumulation, quality ventilation systems maintain healthy indoor environments without compromising the envelope, and consistent temperatures reduce wear on both structural and mechanical systems [14]. It's an investment strategy where energy savings and extended building life work together to maximize return on investment.

Baseline Measurements and Performance Benchmarks

You can't improve what you don't measure - a principle that's especially true for metal building energy performance. Establishing clear baseline measurements provides the foundation for meaningful efficiency improvements and validates the return on your investment.

The benchmarking process begins with gathering comprehensive data about your building's current performance. This includes utility consumption records, building specifications, occupancy patterns, and operational schedules [15]. Many building owners find ENERGY STAR's Portfolio Manager invaluable for this process. As the industry standard covering nearly 25% of U.S. commercial building space, it provides a standardized 1-100 score that compares your building's performance against similar structures nationwide [16].

Understanding your score is straightforward: 50 represents median performance, while higher scores indicate superior efficiency. The system accounts for variables like weather patterns and operating characteristics, ensuring fair comparisons across different regions and building types [16].

Beyond initial benchmarking, ongoing monitoring transforms data into actionable insights. Tools like ENERGY STAR's Energy Tracking Tool enable you to monitor consumption patterns, calculate custom metrics relevant to your operations, and track progress toward specific efficiency goals [17]. This systematic approach helps identify which upgrades deliver the greatest impact and validates that your efficiency investments are performing as expected. With clear metrics in hand, you're equipped to make informed decisions that enhance both immediate performance and long-term value.

Advanced Insulation and Envelope Solutions

Which insulation system delivers the best ROI for your specific metal building application?

Comparative Analysis of Insulation Options for Metal Buildings

When selecting insulation for your metal building, understanding the strengths and applications of each option helps you make an informed decision. Let's explore the primary insulation types and their practical benefits:

Fiberglass Insulation remains the go-to choice for budget-conscious projects. This economical option creates thermal resistance by trapping air within glass filaments, providing solid performance at an attractive price point. While installation requires proper safety equipment, fiberglass offers natural fire resistance and works well for most standard applications.

Spray Foam Insulation excels where air sealing is critical. Available in both open-cell (for interior applications) and closed-cell (for moisture-prone areas) variants, spray foam creates an airtight barrier that eliminates gaps and cracks. Though professional installation increases initial costs, the superior thermal performance often justifies the investment for temperature-sensitive operations.

Rigid Foam Board provides consistent, high-performance insulation ideal for projects requiring predictable R-values across large surfaces. These boards install cleanly on walls, ceilings, and foundations, maintaining their insulating properties without settling or compression over time.

Insulated Metal Panels (IMPs) represent the premium solution for facilities demanding precise climate control. By sandwiching high-performance foam cores between metal facings, IMPs deliver both structural support and superior insulation in a single component. This integrated approach streamlines construction while maximizing energy efficiency—particularly valuable for pharmaceutical, food processing, or data center applications.

Reflective Insulation works differently, bouncing radiant heat away from your building rather than slowing its transfer. This aluminum-faced barrier excels in hot climates and offers additional benefits: it's fully recyclable, naturally fire-resistant, and impervious to moisture.

Understanding R-values (thermal resistance) and U-values (heat transfer rates) helps you compare these options objectively. While R-values provide a standardized comparison across products, U-values tell the complete story of how your entire wall or roof assembly will perform.

Double-Layer and Continuous Insulation Systems: Cost vs. Value

Today's energy codes demand more sophisticated insulation approaches than the single-layer systems of the past. Let's examine how modern multi-layer systems deliver both code compliance and exceptional value:

Double-Layer Systems have become the new standard for good reason. The installation process strategically addresses compression issues that plagued older methods:

- First layer: Faced insulation installed between purlins with supportive metal banding

- Second layer: Unfaced insulation laid perpendicular over the first

- Result: Higher effective R-values and dramatically reduced thermal bridging

Continuous Insulation takes thermal performance even further by creating an unbroken barrier across your entire building envelope. Rigid foam boards installed over structural members eliminate the heat transfer paths that rob traditional systems of efficiency. This approach proves particularly valuable in extreme climates where every degree matters.

The Investment Perspective strongly supports these advanced systems. Consider a typical 40'x60' metal building:

- Initial investment: $2,400-7,000 for R-30 double-layer insulation

- Monthly energy savings: Approximately $125

- Payback period: Under 2 years

- Additional benefits: Enhanced acoustic control and improved occupant comfort

Fabric Liner Systems represent the cutting edge for projects demanding maximum performance. While installation requires more specialized expertise, these systems create an exceptional air and vapor barrier while accommodating thick insulation layers. The fabric membrane, supported by metal banding beneath the purlins, enables installation of multiple insulation layers without compression—achieving performance levels that exceed traditional approaches.

Each system offers distinct advantages, and selecting the right approach depends on your specific performance requirements, budget parameters, and local code requirements. Our team can help evaluate which solution delivers optimal value for your project.

Addressing Thermal Bridging and Air Infiltration Points

As discussed in "Understanding the Energy Dynamics of Metal Buildings," thermal bridging presents unique challenges in steel construction. Here, we'll focus on practical solutions to address these critical energy loss points:

Strategic Thermal Breaks form your first line of defense:

- Thermal spacer blocks between roof sheets and purlins interrupt heat transfer paths

- Thermal break tape applied between wall girts and sheeting provides essential separation

- These simple additions yield significant performance improvements in both single and double-layer systems

Air Infiltration Control requires equal attention, as even the best insulation fails when air moves freely through your envelope. Common problem areas include:

- Building envelope connections where different materials meet

- Utility penetrations for electrical, plumbing, and HVAC services

- Transitions between wall and roof assemblies

Comprehensive Solutions combine multiple strategies for maximum effectiveness:

- Spray foam excels at sealing irregular gaps while providing insulation value

- Continuous rigid board systems maintain consistent thermal resistance across structural members

- Properly detailed connections ensure insulation continuity throughout the assembly

Performance Standards guide proper implementation. Most current energy codes require:

- Minimum R-3 thermal blocks for standard applications

- R-5 blocks for high-performance Long Tab Banded systems

- Verification of installed U-values to confirm code compliance

Success lies in treating thermal bridging and air infiltration as interconnected challenges requiring coordinated solutions. A systematic approach during design and construction prevents the energy loss, condensation problems, and comfort issues that plague poorly detailed metal buildings.

Budget-Friendly Insulation Strategies with Maximum ROI

Smart insulation decisions balance upfront costs with long-term savings. Here's how to maximize your return on investment while meeting your performance needs:

The Fiberglass Foundation provides excellent value for most applications:

- R-values from R-8 to R-30 accommodate various climate zones

- Installation costs for a 40'x60' building typically range from $2,400-7,000

- Double-layer systems optimize this investment by eliminating compression points and thermal bridges

High-Performance Alternatives justify their premium when conditions demand:

- Fabric liner systems excel where air quality and moisture control are critical

- Closed-cell spray foam (R-6.0 to R-8.0 per inch) serves areas prone to condensation

- Enhanced acoustic control comes as a bonus with these advanced systems

Strategic Decision Factors should guide your selection process:

- Building Use: Cold storage demands different solutions than general warehousing

- Climate Zone: Local codes establish minimum requirements, but exceeding them often proves profitable

- Operational Hours: 24/7 facilities see faster payback on insulation investments

- Budget Timeline: Consider both installation costs and energy savings over your planning horizon

Maximizing Your Investment requires looking beyond initial costs. A properly insulated metal building can achieve energy savings that repay your investment in under two years—then continue delivering savings for decades. The key lies in selecting the right system for your specific application rather than defaulting to the lowest bid.

Our design team specializes in analyzing these factors to recommend insulation strategies that align with both your immediate budget and long-term operational goals. By considering your complete project requirements, we help ensure your insulation investment delivers maximum value throughout your building's lifecycle.

Structural Design Elements for Optimal Efficiency

Cool roof technologies can maintain temperatures up to 60°F cooler than traditional black roofs.

Energy-Efficient Roof Systems and Cool Roof Technologies

When designing energy-efficient metal buildings, cool roof technologies stand out as a premier solution for reducing operational costs. In our experience working with commercial property owners, these advanced roofing systems can maintain temperatures up to 60°F cooler than traditional black roofs during peak summer months. This remarkable performance comes from maximizing two critical properties: solar reflectance (also known as albedo) and thermal emittance.

The most effective cool roof solutions utilize specialized materials - from reflective membranes and coatings to metal panels engineered to reflect sunlight while efficiently releasing any absorbed heat. When selecting the appropriate system, we consider the building's slope carefully. Low-slope applications typically benefit from different materials than steep-slope designs, with options ranging from reflective membranes and specialized coatings to stone-ballasted systems and treated metal tiles.

The benefits extend well beyond individual building performance. Cool roofs actively reduce urban heat island effects and can lower indoor temperatures by 2.2-5.9°F in non-conditioned spaces, improving comfort for workers and reducing strain on adjacent air-conditioned areas. While it's true that cool roofs may marginally increase winter heating needs in colder climates, this minor 'heating penalty' is consistently offset by substantial summer cooling savings - particularly given lower winter sun angles and shorter daylight hours.

From an investment perspective, the Federal Energy Management Program confirms that ENERGY STAR-qualified cool roof products deliver strong returns when priced within $0.64/ft² above standard roofing. Top-performing models can save up to $1.11/ft² over their operational lifetime, making them a smart choice for long-term value.

Strategic Window, Door, and Opening Placement and Selection

Strategic window and door placement forms a cornerstone of energy-efficient metal building design. Through years of helping clients optimize their facilities, we've seen how properly selected windows can dramatically reduce electricity costs while enhancing occupant comfort and productivity through natural daylighting.

For metal building applications, high-performance vinyl-frame windows prove particularly effective. Their superior insulation properties and natural corrosion resistance make them ideal partners for steel structures. Double-pane construction further enhances thermal performance, creating a barrier against heat transfer that complements the building's insulation system.

Placement strategy requires thoughtful planning. South-facing windows capture maximum natural light throughout the day, though we always recommend incorporating proper overhangs to control seasonal heat gain and glare. When designing for natural ventilation, operable windows should be positioned to establish cross-airflow patterns that continuously refresh indoor air without relying on mechanical systems.

The installation process demands meticulous attention to detail. Every window must be properly sealed with butyl tape or appropriate sealant around the entire perimeter, with exterior trim specifically designed to channel water away from the building envelope. While retrofitting windows remains possible, incorporating them during initial design proves far more cost-effective and ensures proper structural support.

The primary challenge stems from steel's thermal conductivity - conducting heat 400 times more effectively than wood. This characteristic makes comprehensive insulation and air sealing around all openings absolutely essential for maintaining the building's energy efficiency targets.

Building Orientation and Layout Optimization

Building orientation and layout optimization represents a fundamental opportunity to reduce energy consumption through intelligent design. As experienced steel building professionals, we guide clients to position their structures to maximize natural advantages while minimizing environmental challenges.

The building's orientation should capitalize on solar patterns and prevailing winds specific to your site. As discussed in window placement above, south-facing exposures with properly designed overhangs provide optimal daylighting while managing seasonal heat gain. However, orientation planning extends beyond fenestration to encompass the entire building envelope and its relationship to the site.

Interior layout design proves equally critical for passive efficiency. We recommend positioning high-heat processes and equipment rooms along north walls or in areas with enhanced ventilation capacity, keeping them separated from occupied spaces to reduce cooling demands. Conversely, offices and workspaces benefit from placement near insulated walls and beneath properly ventilated roof sections, creating comfortable environments with minimal mechanical intervention.

Strategic placement of louvers, vents, and other openings establishes natural airflow patterns throughout the structure. These elements work in concert to create a breathing building that maintains air quality and temperature control through passive design principles. This holistic approach to orientation and layout not only reduces operational costs but creates more pleasant, productive environments for building occupants.

Pre-Engineered Systems and Their Efficiency Advantages

Pre-engineered metal buildings (PEMBs) represent the pinnacle of efficient structural design, combining speed, precision, and sustainability. Through factory-controlled fabrication, these systems achieve construction time reductions of up to 50% while lowering costs by 30% compared to traditional building methods. This efficiency extends beyond the construction phase - the streamlined design and manufacturing process creates smaller environmental footprints from day one.

Modern PEMBs incorporate recycled steel content ranging from 30% to 74%, depending on the manufacturer and application. This sustainable approach combines with engineering precision to minimize waste throughout the building lifecycle. The modular nature of these systems allows for future expansions and modifications without compromising the original structure's integrity or efficiency.

From an energy performance perspective, PEMBs excel through their integrated design approach. Factory-engineered connections ensure precise fit-up that eliminates gaps and thermal bridges common in field-fabricated structures. This precision translates directly to energy savings - properly sealed buildings maintain consistent interior temperatures with less mechanical intervention.

The adaptability of pre-engineered systems extends to incorporating advanced efficiency features. Whether integrating insulated metal panels, solar-ready roof structures, or smart building technologies, PEMBs provide the flexibility to meet evolving efficiency standards while maintaining structural integrity and aesthetic appeal.

Mechanical and Electrical Systems Integration

Can smart building automation reduce your metal building's energy consumption by nearly 30%?

Right-Sizing HVAC Systems for Metal Building Applications

Right-sizing HVAC systems for metal buildings starts with understanding how the building envelope performs as a complete system. Your HVAC efficiency depends directly on the quality of your insulation and how well it's installed throughout the roof and wall assemblies. When calculating system requirements, consider all heat sources and losses: occupancy levels, equipment loads, lighting heat, and the thermal performance of windows and doors.

Metal buildings present unique sizing challenges that traditional calculations often miss. Compressed insulation around purlins can reduce your expected R-value by up to 50%, significantly impacting heating and cooling loads. This is why we emphasize an integrated design approach - your HVAC and insulation systems work together, not independently. Modern solutions like insulated metal panels provide consistent thermal performance that simplifies HVAC sizing while ensuring optimal efficiency.

Air infiltration represents another critical factor often underestimated in metal buildings. Poor envelope sealing forces HVAC systems to work harder, leading to oversized equipment that cycles frequently and operates inefficiently. By addressing air sealing during construction and properly calculating infiltration rates, we can specify systems that maintain comfort without wasting energy or capital on unnecessary capacity.

Energy-Efficient Lighting Solutions and Controls

LED lighting transforms metal building energy efficiency by cutting operational costs up to 50% compared to fluorescent systems. Beyond the immediate savings, LEDs provide superior light distribution that enhances workplace productivity and safety - crucial factors for industrial and commercial facilities.

Today's advanced lighting controls take efficiency even further. Motion sensors and daylight harvesting systems work together, automatically dimming or brightening based on natural light levels and occupancy. This intelligent approach ensures you're never paying to light empty spaces or over-illuminating areas with abundant natural light.

For facility managers, multi-circuit electronic controls offer unprecedented flexibility. Create custom 365-day schedules for different building zones - keep security lighting active 24/7 while programming warehouse lighting to match shift schedules. The latest Bluetooth mesh technology puts control at your fingertips through smartphone apps, allowing real-time adjustments to lighting levels, sensor sensitivity, and operational schedules. These smart systems maintain energy code compliance automatically while delivering the lighting performance your operations demand.

Smart Building Automation for Optimized Energy Management

Building automation systems (BAS) represent the future of metal building efficiency, creating an intelligent network that monitors and optimizes every aspect of your facility's operation. By connecting HVAC, lighting, security, and other systems through a central platform, BAS transforms reactive maintenance into proactive energy management.

Modern automation goes far beyond simple scheduling. Smart metering provides real-time energy usage data, while load shedding capabilities automatically reduce power consumption during peak rate periods - protecting your bottom line when utility costs spike. The system continuously analyzes operational patterns, detecting anomalies before they become costly problems and scheduling maintenance based on actual equipment performance rather than arbitrary timelines.

The potential impact is substantial: Department of Energy studies show that comprehensive BAS implementation can reduce commercial building energy consumption by nearly 30%. Yet only 15% of U.S. commercial buildings currently leverage this technology, presenting a significant opportunity for forward-thinking owners.

Beyond energy savings, BAS provides valuable operational insights through occupancy analytics and movement patterns. This data helps optimize space utilization and workflow efficiency. When integrated during the design phase through Building Information Modeling (BIM), these systems ensure your metal building operates at peak efficiency from day one.

Ventilation Strategies That Maintain Efficiency and Indoor Air Quality

As discussed in the Building Orientation and Layout Optimization section, effective ventilation requires strategic planning from the design phase. For metal buildings, the key is creating systems that maintain air quality without compromising the energy efficiency you've worked hard to achieve.

Natural ventilation through ridge vents remains one of the most cost-effective solutions, using simple convection to exhaust hot air while drawing cooler air through lower openings. However, many industrial and commercial applications demand more precise control. That's where mechanical ventilation systems prove their worth, ensuring consistent air circulation regardless of outdoor conditions or internal heat loads.

The most sophisticated approach combines both strategies through hybrid ventilation systems. Energy recovery ventilators (ERVs) and heat recovery ventilators (HRVs) capture thermal energy from exhausted air, pre-conditioning incoming fresh air to reduce HVAC loads. This technology is particularly valuable in extreme climates where the temperature differential between indoor and outdoor air represents significant energy loss.

Moisture control deserves special attention in metal buildings. Beyond general ventilation, high-risk areas like wash bays, kitchens, or processing areas need dedicated spot ventilation to prevent condensation that could compromise your building's integrity. Establish a maintenance schedule that includes biannual inspections of all ventilation components - a small investment that prevents costly moisture damage and maintains optimal air quality for occupants.

Regulatory Compliance and Implementation Considerations

Meeting energy codes requires advanced insulation systems and continuous air barriers in metal buildings.

Navigating ASHRAE 90.1 and IECC Requirements for Metal Buildings

Metal buildings must comply with two primary energy codes: ASHRAE 90.1, which establishes minimum standards for energy efficiency, and the International Energy Conservation Code (IECC), which references ASHRAE standards. Understanding these requirements is essential for ensuring your building meets current regulations while maximizing efficiency.

The most widely adopted versions - IECC 2015 and ASHRAE 90.1-2013 - mandate specific insulation values and thermal performance requirements that directly impact your building design. These codes require precise U-values for different building components. For instance, in climate zone 5a, ASHRAE 90.1-2013 requires a roof U-value of .037 and a wall U-value of .050. Meeting these stringent requirements typically necessitates advanced insulation systems such as liner systems or filled cavity installations with long tab banding.

Air barrier requirements have become increasingly important in recent code updates. Both IECC 2015 and ASHRAE 90.1-2013 require continuous air barriers across all joints and assemblies, with properly sealed penetrations and detailed documentation in construction drawings. Your project can demonstrate compliance through three distinct pathways: materials testing under ASTM E2178, assembly testing under ASTM E2157, or whole building testing using ASTM E779.

The 2022 edition of Standard 90.1 has introduced over 80 updates to energy efficiency requirements, affecting both new construction and existing building modifications. These evolving standards underscore the importance of working with experienced steel building professionals who stay current with regulatory changes and can guide you through compliance while optimizing your building's performance.

Green Building Certifications and Their Economic Benefits

Green building certifications like LEED offer compelling economic advantages while demonstrating environmental responsibility. Buildings achieving these certifications typically reduce energy consumption and CO2 emissions by up to 40% compared to conventional structures, making them increasingly attractive to quality tenants and forward-thinking investors.

The financial benefits of green certification extend well beyond operational savings. Certified buildings consistently command higher property values and rental rates, while enjoying improved marketability and longer economic lifespans. They also face reduced risks of technical and regulatory obsolescence - a critical consideration as environmental regulations continue to tighten. For organizations committed to sustainability goals, green-certified buildings provide a tangible way to reduce their carbon footprint, particularly important as buildings account for nearly 40% of global energy-related emissions.

Metal buildings possess inherent advantages in achieving green certifications. Steel components typically contain 30-50% recycled content and remain virtually 100% recyclable at the end of their service life. The uniform structural framing characteristic of metal buildings provides exceptional flexibility for incorporating high-performance features like insulated metal panels, advanced daylighting systems, and renewable energy integration. These attributes, combined with the durability and low maintenance requirements of steel construction, position metal buildings as ideal candidates for green certification programs.

New Construction vs. Retrofit Approaches and Strategies

When considering energy efficiency improvements, building owners face a strategic choice between retrofitting existing structures and investing in new construction. Each approach offers distinct advantages that deserve careful consideration based on your specific situation and goals.

Retrofitting existing metal buildings provides an attractive option for achieving significant efficiency improvements while managing costs. By leveraging your existing structural elements, retrofit projects can dramatically reduce energy consumption and carbon emissions while increasing property values and enhancing occupant comfort. Strategic upgrades to insulation, HVAC systems, and the building envelope can transform an older structure into a high-performance facility. For existing buildings, certified fiberglass metal building insulation delivers exceptional returns on investment by reducing thermal transfer through walls and roofs while protecting against moisture-related issues.

The financial incentives for retrofitting are compelling. Building owners can qualify for substantial tax deductions - up to $1.80 per square foot when achieving 50% energy savings, or $0.60 per square foot for improvements delivering 16.67% savings. These incentives can significantly offset project costs while delivering ongoing operational savings.

New construction projects, while requiring higher initial investment, offer the opportunity to incorporate cutting-edge efficiency technologies from the ground up. Double-layer insulation systems, advanced building automation, and integrated renewable energy systems can be seamlessly designed into the structure. This comprehensive approach often results in superior long-term performance and lower total lifecycle costs, making it an excellent choice when expansion or replacement is already under consideration.

Quality Assurance and Performance Verification Methods

Ensuring your metal building achieves its designed energy efficiency requires systematic quality assurance throughout the project lifecycle. This comprehensive approach protects your investment and guarantees the performance benefits you're expecting.

The quality assurance process begins during design with thorough documentation of all system specifications and performance requirements. This foundation enables accurate verification as construction progresses. During the build phase, rigorous testing confirms that each component and system meets its intended design goals - from insulation installation to mechanical system integration.

Performance verification encompasses comprehensive evaluation of all building systems. This includes functional testing of mechanical, electrical, and plumbing systems to examine equipment operation, control sequences, and how different systems work together. Critical verification steps include conducting detailed load calculations, measuring actual system performance against design parameters, and maintaining thorough documentation of all test results and operational data.

The commissioning process serves as your final quality checkpoint, providing systematic testing and documentation to verify that all building systems meet both design intent and your specific requirements. This includes confirming proper installation, conducting functional performance testing, and ensuring all systems operate at peak efficiency from day one.

Quality assurance doesn't end at project completion. Regular monitoring and periodic retro-commissioning help maintain optimal performance throughout your building's lifecycle. This proactive approach identifies and addresses any efficiency degradation before it impacts your operational costs, ensuring your energy-efficient metal building continues delivering expected savings year after year.

Economic Analysis and Long-Term Financial Benefits

How quickly can energy efficiency investments pay for themselves in metal buildings?

Calculating True Lifetime ROI of Energy Efficiency Investments

Understanding the true financial return on energy efficiency investments in metal buildings requires looking beyond simple payback calculations. At National Steel Buildings Corp, we help clients develop comprehensive ROI analyses that capture the full spectrum of benefits. The basic calculation involves dividing net profit by investment cost and multiplying by 100, but this only tells part of the story [55]. A thorough analysis must factor in both immediate savings and long-term value creation.

Professional energy audits establish crucial baseline data, systematically evaluating your building's current consumption patterns and identifying specific opportunities for improvement [56]. Our experience shows that properly implemented efficiency measures in metal buildings can achieve energy savings of up to 25%, with the greatest returns coming from facilities with higher baseline consumption [57].

The complete ROI picture incorporates multiple value streams: direct energy cost reductions, decreased maintenance expenses, extended equipment life, and available tax incentives [55]. For metal building projects specifically, we recommend tracking operational improvements through integrated monitoring systems and control panels that provide real-time verification of projected versus actual savings [57]. These advanced management systems not only validate your investment but also enable continuous optimization of building performance [57].

Extended Building Lifespan and Reduced Maintenance Costs

The financial advantages of energy-efficient metal buildings compound significantly through their exceptional lifespan and minimal maintenance requirements. Steel's inherent durability eliminates costly issues that traditional materials face - no termite damage, rot, or moisture deterioration means your investment remains protected for decades [13]. Research confirms that well-designed metal buildings maintain full functionality for 60+ years with minimal upkeep, while conventional structures demand frequent repairs and component replacements [58].

Modern protective coatings and specialized finishes shield metal surfaces from environmental factors, dramatically reducing refurbishment needs [58]. Consider this: metal roofing panels routinely last 50+ years with basic maintenance, while asphalt shingles require replacement every 15-20 years [59]. This durability advantage becomes a powerful financial multiplier over your building's lifetime.

The strength of steel to withstand extreme temperatures and severe weather translates directly to your bottom line through lower total ownership costs [58]. Additionally, insurance companies recognize this superior risk profile, often offering reduced premiums for metal structures. When you factor in these ongoing savings alongside the energy efficiency benefits discussed throughout this guide, the economic case for metal buildings becomes compelling [58].

Energy Modeling and Consumption Prediction Tools

Today's sophisticated energy modeling tools transform how we predict and optimize the financial performance of metal buildings. These Building Performance Simulation (BPS) platforms combine powerful algorithms with intuitive interfaces, enabling precise analysis of energy consumption patterns and operational costs before construction begins [60]. By evaluating multiple design scenarios simultaneously, tools like cove.tool help identify the optimal combination of features to maximize your return on investment [60].

For projects requiring detailed thermal analysis, platforms such as OpenStudio provide comprehensive modeling of heat flows and energy networks, ensuring your insulated metal panels and other efficiency features perform as expected. The National Renewable Energy Laboratory's URBANopt™ takes this further, enabling district-scale modeling that considers how your building interacts with neighboring structures and renewable energy systems [61].

These modeling capabilities prove invaluable for securing financing and demonstrating compliance with energy codes. By providing detailed predictions of energy savings, maintenance costs, and equipment lifecycles, these tools help justify the initial investment in high-performance systems. Our team leverages these platforms to optimize every aspect of your building's design, ensuring maximum efficiency and financial return throughout its operational life.

Available Incentives, Tax Benefits, and Financing Options

Federal tax incentives significantly enhance the ROI of energy-efficient metal buildings through IRC Section 179D, recently expanded under the Inflation Reduction Act. Commercial building owners can claim substantial deductions for both new construction (EECBP) and retrofits (EEBRP), with benefits multiplying approximately 5x when meeting prevailing wage and apprenticeship requirements [62]. For properties placed in service from 2023 onward, deductions equal the lesser of actual installation costs or calculated maximum savings per square foot [62].

The Department of Energy's free 179D Portal helps estimate your potential deductions for qualifying metal building upgrades, making it easier to factor these benefits into your investment analysis [63]. These incentives apply to many of the efficiency features discussed throughout this guide, from advanced insulation systems to smart building controls.

For residential metal building applications, federal tax credits extend through 2025, offering up to $3,200 annually for qualifying improvements. This includes up to $2,000 for heat pump installations and $1,200 for other efficiency upgrades, plus an additional 30% credit for renewable energy systems like solar panels - which integrate exceptionally well with metal roofing systems [64]. These credits have no lifetime limits and can be claimed each year through 2025, though they apply primarily to principal residences [64].

Understanding and leveraging these incentives is crucial for maximizing your metal building investment. We recommend consulting with tax professionals to ensure you capture all available benefits for your specific project.

Conclusion

Energy-efficient metal buildings deliver returns that compound over decades of reliable service.

Summary of Key Energy Efficiency Strategies and Their Benefits

The journey to maximizing energy efficiency in metal buildings involves multiple integrated strategies working in harmony. From advanced thermal envelope solutions to smart building technologies, each component plays a vital role in creating structures that perform optimally while minimizing operational costs. As we've explored throughout this guide, proper implementation of insulated metal panels, continuous insulation systems, and strategic thermal breaks addresses the unique challenges of steel construction while leveraging its inherent strengths. Cool roof technologies, optimized HVAC systems, and intelligent building automation further enhance performance, creating facilities that adapt to changing conditions while maintaining optimal efficiency. The cumulative effect of these strategies - when properly designed and executed - delivers energy savings of 15-30% compared to traditional construction methods, with payback periods often under two years.

The Compounding Value of Efficiency Investments Over Time

The financial advantages of energy-efficient metal buildings extend far beyond initial cost savings. As demonstrated in our economic analysis, the compounding effect of reduced construction costs, minimal maintenance requirements, and lower operational expenses creates substantial long-term value. Each efficiency investment - whether in superior insulation, automated controls, or renewable energy integration - contributes to a cascade of benefits that multiply over the building's lifespan. The durability inherent in steel construction ensures these efficiency gains persist for decades, while the adaptability of metal structures allows for future upgrades as new technologies emerge. This creates a resilient investment that not only reduces environmental impact but also positions building owners for sustained profitability in an increasingly energy-conscious market.

Next Steps for Building Owners and Project Managers

Taking action on energy efficiency requires a strategic approach tailored to your specific building needs and operational goals. Start with a professional energy assessment to establish your baseline and identify the most impactful opportunities for your facility. Focus on envelope improvements first - proper insulation and air sealing provide the foundation for all other efficiency measures. Next, evaluate your mechanical systems to ensure they're appropriately sized and optimized for your improved building envelope. Consider integrating renewable energy solutions where feasible, as these investments continue to deliver returns as energy costs rise. Most importantly, partner with experienced professionals who understand the unique characteristics of metal building systems and can guide you through the implementation process. At National Steel Buildings Corp, we're committed to helping you achieve your efficiency goals while maximizing the value of your investment. Contact us today to learn how our integrated approach to energy-efficient metal building design can transform your next project into a model of sustainability and profitability.

- Metal buildings account for nearly 30% of low-rise commercial construction and can achieve energy savings of 15-30% with proper design

- Steel's high conductivity requires specialized insulation strategies, but wider structural spacing creates opportunities for deeper insulation cavities

- Double-layer insulation systems typically cost $2,400-7,000 for a 40'x60' building with payback periods under 2 years

- Cool roof technologies can maintain temperatures up to 60°F cooler than traditional roofs, saving up to $1.11/ft² over their lifetime

- Building automation systems can reduce commercial energy use by nearly 30%, yet only 15% of U.S. buildings currently use this technology

- Federal tax incentives through IRC Section 179D offer deductions up to $1.80/ft² for achieving 50% energy savings

- Properly designed metal buildings can last 60+ years with minimal maintenance, while metal roofing panels last 50+ years

- LEED-certified buildings reduce energy consumption and emissions by up to 40% while commanding higher property values

- The buildings sector, which includes energy used for constructing, heating, cooling and lighting homes and businesses, as well as the appliances and equipment installed in them, accounts for over one third of global energy consumption and emissions. - https://www.iea.org/energy-system/buildings

- Already facing inflationary pressure and supply constraints, many fabricators are now signaling 10–12% pre-summer price increases, with additional hikes likely as ripple effects take hold. - Industry analysis, 2025

- In fact, industry studies show that energy costs in pre-engineered metal buildings can be up to 40% lower than those in traditional buildings - https://westernsteel.com/the-future-of-commercial-construction-metal-buildings/

- Metal building systems continue to grow in popularity, with theMetal Building Manufacturers Association(MBMA), noting that metal building systems account for nearly 30% of all low-rise commercial construction in the U.S... The deeper structural members of metal buildings range from 6 inches to 12 inches deep, creating more space for insulation... spacing of studs in wood structures are often 16 inches apart, far more frequent than the spacing of metal building members, which is often 5 feet on the roof - https://www.metalarchitecture.com/articles/metal-buildings-and-energy-loss/

- The adaptability of steel allows for the integration of high-performance insulation systems within the building's framework. Rigid foam panels, spray foam insulation, and reflective barriers can be seamlessly incorporated into steel structures, creating a highly efficient thermal envelope... the design versatility of steel buildings allows for the integration of renewable energy systems such as solar panels and wind turbines. - https://lionbuildings.com/why-are-steel-buildings-so-energy-efficient/

- According to a report by the International Energy Agency (IEA), energy-efficient renovations can reduce energy consumption in buildings by up to 40%. - https://www.kaarwan.com/blog/architecture/economic-benefits-energy-efficient-buildings-cost-savings-return-on-investment?id=1114

- Metal buildings require minimal repairs, have lower insurance premiums, and offer superior energy efficiency, reducing operational costs. Their ability to resist fire, pests, and harsh weather conditions further minimizes expenses. - https://www.hswilliams.com/blog/commercial-metal-buildings-cost-vs-value-analysis

- Structural steel is so strong that columns can be spaced 25-feet apart, not inches. In addition, wood framing walls are only 3.5-inches thick. Light-gauge steel construction typically creates 6-inch thick walls. However, commercial-grade steel creates wall cavities nine-inches deep — or more! - Metal Building Design Standards

- Metal is a highly conductive material, which means it transfers heat and cold very efficiently. This can lead to several issues if insulation is not properly installed - https://www.whirlwindsteel.com/2025/04/30/a-guide-to-metal-building-insulation/

- Considering global energy crisis, the enhancement of energy management in industries and buildings utilizing various thermal insulation materials, such as metallic heat insulator, aerogels, and phase change materials (PCMs), seems very important - https://www.sciencedirect.com/science/article/pii/S2352710221004629

- Thermal bridging occurs when a more conductive (i.e. something with a poor insulating value) element creates an easy pathway for heat flow across a thermal barrier. The end result? Everyone's worst nightmare: Heat loss and the potential for condensation. - Building Science Corporation

- Metal buildings are renowned for their exceptional durability and long lifespan. By choosing metal as a construction material, you are opting for a sturdy and resilient structure that can withstand various environmental challenges, including high winds, heavy snow loads, and seismic activity. - https://www.fswest.com/energy-efficiency-of-metal-buildings/

- High-performance insulation available for steel structures keeps air from escaping your facility. That means you'll have less heat escape in the winter and less cool air escape in the summer, so your air conditioning isn't constantly running. - https://cdmg.com/building-faqs/how-do-metal-buildings-reduce-energy-costs

- Metal building systems can be designed to comply with the energy code requirements anywhere in North America. MBMA offers a wide range of resources to assist design professionals in choosing the best components to meet those codes. - https://mbma.com/energy-sustainability

- Gather Utility Data(electricity, gas, water, or steam) and details about the building(s), such as size, type, and occupancy levels. This will typically give you the information you need to get started. - https://energysciencesllc.com/sustainability/benchmarking-101/

- Nearly 25% of U.S. commercial building space is already actively benchmarking in Portfolio Manager, making it the industry-leading benchmarking tool... The ENERGY STAR score compares your building's energy performance to similar buildings nationwide, normalized for weather and operating characteristics. A score of 50 represents median performance. - https://www.energystar.gov/buildings/benchmark

- EPA offers theEnergy Tracking Tool(and a complimentaryQuick Start Quide), a simple means for tracking energy performance over time and progress toward meeting goals. The tool enables users to track monthly or annual energy data for facilities and the entire organization, reporting out custom energy intensity metrics - https://www.energystar.gov/industrial_plants/measure-track-and-benchmark/tools-tracking-and

- Fiberglass is the most common type of insulation material used in residential and commercial projects. In making fiberglass, glass is heated and forced through superfine holes to create microthin glass filaments. - Insulation Institute

- Spray foam insulation offers superior thermal resistance and seals gaps effectively—preventing air leaks. It comes in two forms: open-cell and closed-cell. - https://www.rmax.com/blog/metal-building-insulation

- Traditionally, a single layer of fiberglass blanket insulation draped over the purlins has been used... This low-cost design no longer meets the energy codes because the blankets are squished over the purlins by metal roofing, and their insulating properties are greatly degraded... The first layer of faced insulation is installed between the purlins and on the metal support banding. The second layer of unfaced insulation is then installed over the first layer... The fabric liner is installed below the roof purlins, supported by metal banding. Then the first layer of unfaced fiberglass is installed between the purlins and over the liner system. - https://www.buildingsguide.com/build/metal-building-insulation/?srsltid=AfmBOooaYq9rtnP29YfaHPxrDKODacyhVjUVw6yjKfDsQnW3foE_T0Yu

- When properly installed, they create a continuous, gapless barrier across all structural parts, preventing thermal bridging and heat loss or gain through the building's structure... After deducting the construction cost and materials, you should budget between $2,400 and $7000 to insulate a standard size 40'X60′ metal building. If you insulate your steel building and save, say, $125 a month on energy expenses, you may recover the cost of your original insulation expenditure in overtwo years. - Energy Efficiency Standards Report

- The R-value of an insulation product is a thermal resistance rating that tells us how well a material resists heat flow. The higher the R-value, the better the insulation performs at restricting heat transfer. R-values for metal building insulation range from R-8 to R-30. - https://therm-all.com/a-guide-to-metal-building-insulation/

- The first layer of faced insulation is installed between the purlins and on the metal support banding. The second layer of unfaced insulation is then installed over the first layer. - https://www.buildingsguide.com/build/metal-building-insulation/?srsltid=AfmBOooe6CHZwk2yJOEh5abMAbC4T6KNObU3cjWbHQiJWtNAkJL6iosY

- Closed-cell spray foam insulation has an R-value of R-6.0- R-8.0 per inch. - https://www.westernstatesmetalroofing.com/blog/metal-roofing-building-insulation

- Cool roofs stay up to 60°F cooler than traditional black roofs during the summer... FEMP has calculated that the required ENERGY STAR-qualified cool roof product saves money if priced no more than $0.64/ft2... The best available model saves up to $1.11/ft2 - https://www.energy.gov/femp/purchasing-energy-efficient-cool-roof-products

- Some common cool roof materials include membranes, shingles, coatings, stone/rock, metal, and tile with high solar reflectance. - https://www.energystar.gov/products/cool-roofs

- A high solar reflectance, or albedo, is the most important characteristic... in non-air-conditioned residential buildings, cool roofs can lower maximum indoor temperatures by 1.2–3.3°C (2.2 to 5.9°F)... However, this so-called 'heating penalty' is typically offset by summer cooling energy savings. - https://www.epa.gov/heatislands/using-cool-roofs-reduce-heat-islands

- Window Placement: Proper placement of windows is essential for optimizing daylighting in your metal building. When designing your building, carefully consider the orientation and size of windows to maximize the entry of natural light. South-facing windows tend to receive more sunlight throughout the day, while overhangs or shades can help control the amount of light and heat entering the building. - https://www.metalbuildingoutfitters.com/creating-energy-efficient-metal-buildings-customization-and-features-guide/

- Generally, windows with vinyl frames are the best choice. Vinyl is an excellent insulator, it won't corrode from contact with the steel panels, and it's extremely durable and low-maintenance, making them very energy-efficient... Every window is installed with a butyl tape or sealant bead around the entire perimeter to create a watertight barrier. The exterior trim is then designed to channel water away from the opening, ensuring a leak-proof installation. - https://steelbuildingstores.com/accessories/windows-for-metal-buildings/

- The biggest challenge with making metal buildings energy efficient is the steel itself which is 400x more conductive than wood. You need to pay attention to thermal bridging far more with steel buildings than wood. - https://www.greenbuildingadvisor.com/question/high-performance-metal-building-home

- Design influences how energy is used and retained within a building. During remodeling, design decisions can be made to support passive efficiency strategies. These involve using the building's structure and orientation to reduce reliance on mechanical systems... Interior space layout also plays a role. Areas that require more heating or cooling can be placed near insulated walls or beneath ventilated roofs. Equipment rooms and high heat zones can be positioned away from occupied spaces to reduce cooling demands... Natural ventilation through operable windows or strategically placed vents can also be effective in certain climates. Cross ventilation, where air flows in one side of the building and out the other, supports passive cooling. - https://lionbuildings.com/how-to-make-metal-buildings-more-energy-efficient-while-remodeling/

- With the ability to cut construction time by 50% and reduce costs by 30% compared to traditional building methods - Metal Building Manufacturers Association Study

- Butler Manufacturing, a leader in the industry, has been at the forefront of this movement, utilizing up to 74% recycled steel and engineering buildings that reduce waste, lower energy use, and extend lifespans - https://marbuildingsolutions.com/pre-engineered-building-green-advantages/

- The efficiency of the design process increases the efficiency at the construction phase as well; creating a smaller footprint in environmental impact. Over and above all these things, steel buildings save energy and reduce the greenhouse effect because they are excellent insulators for both heat and cold. - https://norsteelbuildings.com/advantages-of-steel-series/advantages-energy-efficiency/

- The operating efficiency of any HVAC system is directly related to the amount of insulation in the roof and wall and, more importantly, the method in which it is installed in Lhe building. Another important factor is considering the intended building use. What type of equipment and lights will be in operation? How many people will typically occupy the facility? - https://thermaldesign.com/techinfo/newsMain/hvac_sizing_step_1_rethink_your_building_envelope/

- Metal buildings tend to be more susceptible to air infiltration due to poor envelope air sealing, and if an HVAC contractor fails to take this into consideration they may undersize the system(s) or end up with a space that struggles with humidity control - https://www.metalarchitecture.com/articles/hvac-and-the-metal-envelope/

- This cost-efficient troffer not only delivers superior, even light distribution but significantly enhances energy savings compared to traditional fluorescent troffers while reducing operating costs, improving visual comfort and increasing sustainability. - https://www.orionlighting.com/

- Our flagship ET90000 Series allows users to create 365-day schedules across up to 16 circuits. This helps facilities create dynamic, area-specific lighting schedules that cater to business needs. For example, a department store may choose to keep exterior lights (or signage) illuminated 24/7, but designate lights on the sales floor to be on only during shopping hours. - https://www.intermatic.com/resources/newsroom/good-better-best-commercial-lighting-control-solutions

- A Building Automation System is an integrated network of hardware and software designed to monitor and control mechanical, lighting, security, and other building systems. By automating these systems, BAS helps maintain optimal environmental conditions while dramatically reducing energy consumption... Currently, only around 15% of U.S. commercial buildings utilize BAS technology, highlighting vast untapped potential. According to the U.S. Department of Energy, full utilization of advanced BAS could cut commercial energy use by approximately 29%. - https://www.selectlee.com/2025/04/24/how-building-automation-systems-improve-energy-efficiency/

- BAS doesn't just help you save energy – it enables you to save money too. With smart metering, you can track your energy usage in real time and identify where you can cut back per device or section. Plus, in peak demand times, BAS can perform load shedding to reduce power consumption in non-essential areas, thus avoiding higher tariff rates. - https://www.turnerprocess.com/blogs/building-automation-systems-for-energy-conservation

- As hot air rises, it exits through the ridge vents, drawing in cooler air from lower vents or openings. This natural convection process helps maintain a consistent temperature and prevents heat buildup, which is particularly important in warmer climates. - https://cjmetals.com/4-effective-ventilation-strategies-for-metal-buildings/

- Mechanical ventilation is essential for large, busy facilities like manufacturing plants, distribution centers, and other spaces where natural air movement cannot meet air quality demands... Inspect vents, fans, and accessories twice a year - https://www.worldwidesteelbuildings.com/blog/metal-building-ventilation/

- For example, you might consider integrating energy recovery ventilators (ERVs) or heat recovery ventilators (HRVs) to recover energy from exhausted air and recondition it to be used on incoming fresh air. It cuts down on the stress on heating and cooling systems. - https://www.nationwidesteelstructures.com/post/maximizing-energy-efficiency-in-metal-buildings-tips-and-best-practices

- First, ASHRAE 90.1 is a minimum standard of energy efficiency, not a code. The International Energy Conservation Code (IECC) is a model energy code that references the ASHRAE Standard 90.1. - https://insulation.org/io/articles/here-are-the-codes-you-need-for-metal-building-envelope-projects/

- The 2022 edition of Standard 90.1 incorporates over 80 addenda to the 2019 edition. - https://www.ashrae.org/technical-resources/bookstore/standard-90-1

- According to the most recentIPCC report, a "rapid and far-reaching" sustainable transition in land, energy, buildings, transport and cities is needed to meet global carbon reduction goals. Buildings account foralmost 40 percent of global energy-related CO2and will play a major role in a sustainable transformation. - https://www.usgbc.org/press/benefits-of-green-building

- According to European researchers, the economic advantages of green buildings include their "longer economic lives, lower marketability risk, and lower risk of technical and regulatory obsolescence." - https://www.aia.org/resource-center/roi-increasing-asset-values

- Steel roof and wall panel systems, structural members and other steel products are virtually 100% recyclable and contain between 30%-50% or more recycled material. - Steel Recycling Institute

- Retrofitting is the process of enhancing the performance of existing buildings through the addition of new components... One of the key benefits of retrofitting buildings is that this strategy offers a cost-effective alternative to a new build, leveraging an existing building's structure. - https://www.paramountmetalsystems.com/why-retrofit-buildings-instead-of-building-new-ones-expert-insights

- Installing fiberglass MBI in metal buildings, whether in a new building or when retrofitting an existing building, dramatically reduces the amount of energy needed to either heat or cool a metal building. Certified fiberglass MBI provides an extremely cost-efficient method of reducing the thermal transfer of heat through the walls and roof of a metal building, while simultaneously protecting against condensation build-up on the panels. - https://insulation.org/io/articles/energy-saving-metal-buildings/

- Capital spending could reach a high of $1.9 trillion annually between 2036 and 2040. This spending may be partly offset by the resulting reductions in operating costs. - https://www.mckinsey.com/capabilities/sustainability/our-insights/spotting-green-business-opportunities-in-a-surging-net-zero-world/transition-to-net-zero/buildings

- Quality control is critical to construction management, ensuring that projects meet specified standards and deliver durable, safe, and functional structures. - https://www.calahan.com/a-guide-to-metal-building-quality-control-in-construction/

- The prescriptive method is the simplest and most straightforward way to comply with Title 24. It involves following a set of specific requirements for each component of your building, such as the roof, walls, windows, doors, floors, and skylights. - https://www.fswest.com/california-title-24-energy-code-requirements-for-metal-buildings/

- Commissioning is the process of testing, verifying, and documenting the performance of these systems to ensure they meet the design intent and the owner's requirements. It's a critical step in the construction process, and it can make a significant difference in the long-term success of a building. - https://gdiengdesign.com/maximizing-system-performance-and-compliance-the-key-role-of-commissioning-in-mep-design/

- You can calculate ROI by subtracting the actual or estimated income from a project from the actual or estimated costs. That number is the net profit. Then, divide the net profit by the costs. Multiply by 100 to get the percentage. - https://www.saveenergynb.ca/en/education-and-tips/energy-efficiency-articles/how-to-calculate-roi-payback-for-your-energy-efficiency-projects/

- Energy audits are systematic evaluations conducted on buildings, facilities, or industrial processes to identify potential energy-saving opportunities and enhance overall efficiency. They involve a thorough examination of energy consumption, encompassing data collection, analysis, and the formulation of an energy efficiency plan. - https://blog.vertpro.com/how-to-measure-roi-for-energy-efficiency-investments/

- our customers have achieved savings of up to 25% thanks to the use of the Spacewell Energy Platform... monitoring the energy consumption of your buildings through control panels, meters, alert systems, and measurement and verification projects, which are crucial to achieving your organisation's energy savings targets. - https://spacewell.com/resources/blog/the-return-on-investment-of-an-energy-management-system/

- A study by Steel Construction shows that metal structures can last 60 years or more with minimal maintenance compared to other construction materials... The ease of maintenance is further illustrated by the novel finishes and color coatings available, which not only enhance visual appeal but also increase resistance to scratching, fading, and peeling... Insurers recognize the inherent durable nature, leading to potentially lower premiums due to the reduced risk of extensive damage. - https://premierbuildingswesternoklahoma.com/blog/the-economics-of-metal-buildings-cost-savings-and-longevity

- Metal panels boast a lifespan exceeding 50 years with minimal maintenance. They far outlast materials such as asphalt shingles, which often requiring replacement every 15 to 20 years. - https://www.metalconstructionnews.com/articles/features/metal-building-systems-sustainable/

- An emerging marketplace of user-friendlybuilding performance simulation(BPS) tools are helping design teams go beyond simple patterns or precedents toward design decision-making based on robust algorithms that indicate relative potential performance impacts. - https://www.buildingenclosureonline.com/blogs/14-the-be-blog-building-enclosure/post/92681-tools-to-help-you-assess-energy-performance-and-or-operational-carbon

- URBANopt™, a first its kind open-source, modular software development kit for modeling districts, neighborhoods and campuses, is fueling innovation for integrated district-scale energy solutions. URBANopt is built on top of OpenStudio and EnergyPlus®to enable multi-building district-scale modeling - https://www.nrel.gov/buildings/data-tools

- Building owners who place in service energy efficient commercial building property (EECBP) or energy efficient commercial building retrofit property (EEBRP) may be able to claim a tax deduction. An increased deduction may be available for increased energy savings or meeting prevailing wage and apprenticeship requirements. - https://www.irs.gov/credits-deductions/energy-efficient-commercial-buildings-deduction

- DOE's 179d Portal hosts two free tools to estimate potential federal tax deductions for installing eligible energy-efficient technologies in commercial buildings for qualifying upgrades beginning in tax year 2023. - https://www.energystar.gov/about/federal_tax_credits/tax_credits_commercial_buildings

- Through December 31, 2025, federal income tax credits are available to homeowners, that will allow up to $3,200 to lower the cost of energy efficient home upgrades by up to 30 percent. - https://www.energystar.gov/about/federal-tax-credits

- Integrating insulated metal panels (IMPs) is a highly effective solution for improving the energy efficiency of metal constructions. These panels are composite panels consisting of two metal facings surrounding a core of insulating material, such as polyurethane, polyisocyanurate, or mineral wool. - https://www.metalbuildingoutfitters.com/what-are-the-latest-energy-efficient-solutions-for-metal-buildings/

- One of the best ways to improve the energy efficiency of buildings is to control outside air leakage, ensuring that windows, doors, panels, insulation and vapor barriers be detailed and carefully installed to ensure that the air barrier is continuous. - https://www.facilitiesnet.com/designconstruction/article/Understanding-The-Energy-Efficiency-Benefits-of-Metal-Buildings--19270

- With all these advantages, construction of metal buildings can cost 30 to 50 percent less than other methods. - https://fse-ok.com/the-economic-benefits-of-metal-building-systems/

- Your average annual maintenance costs should be estimated at 1% of the total initial cost, equating to around $1,500 to $2,500 annually for the 10,000 square foot building... Estimated annual energy savings are 10-20% on energy bills. For a modest commercial setup, a steel building might save $2,000 to $5,000 per year. - https://www.summitsteelbuildings.com/20-year-cost-comparison

- Reducing the environmental impact of metal warehouse construction involves implementing eco-friendly practices to minimize resource consumption and waste generation... By incorporating a thermal barrier in the design, heat transfer between the interior and exterior of the warehouse is minimized, leading to significant energy savings. - https://www.metalbuildingoutfitters.com/why-choose-energy-efficient-metal-warehouse-construction/

- Performance verification involves comprehensive evaluation of all mechanical, electrical and plumbing systems through functional testing that examines equipment operation, control sequences, and system integration - https://www.uspatriotsteel.com/blog/how-to-reduce-energy-consumption-in-commercial-buildings/

- The way insulation is installed also matters. All roof and wall cavities need to be filled completely to avoid thermal bridging. This refers to points in a building with less insulation, allowing heat loss and condensation. Even small gaps can significantly hinder energy efficiency and moisture build-up, so it's important to properly address key areas like around windows, doors, and the roof. - https://fdc-comp.com/boost-energy-efficiency-of-pembs/