The Ultimate Guide to 30x40 Metal Building Price: 2025 Cost Breakdown

This comprehensive 2025 guide reveals everything you need to know about 30x40 metal building prices, from base kit costs ranging $15-25 per square foot to complete turnkey installations at $24-43 per square foot. The total investment for a 1,200 square foot structure typically falls between $28,800-51,600, influenced by structural options like red iron versus tubular steel, clear-span designs, and roof configurations. Beyond the base price, critical factors include foundation requirements ($9,600-14,400), insulation ($1,200-3,300), and interior finishing costs ($35-110 per square foot). Smart buyers can maximize value through strategic timing, value engineering, and leveraging tax incentives like Section 179 deductions. The guide details long-term benefits including 30-50 year lifespans, 30% lower insurance premiums, and significant energy savings that justify the initial investment.

Introduction

Why 30x40 Metal Buildings Are Increasingly Popular in 2025

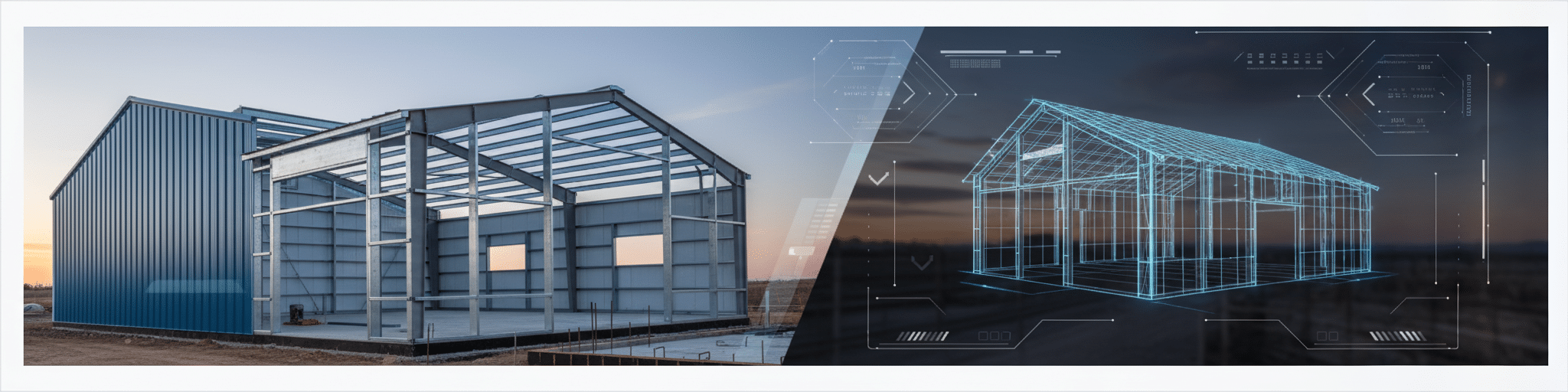

The 30x40 metal building has become one of the most sought-after construction solutions in 2025, and for good reason. These versatile structures offer an ideal balance of space, functionality, and value that appeals to homeowners, business owners, and agricultural operators alike. What makes them particularly attractive is their ability to deliver substantial cost savings while providing a durable, low-maintenance building that adapts to virtually any use.

Modern metal buildings have evolved far beyond their industrial roots. Today's designs seamlessly blend practical functionality with contemporary aesthetics, featuring sleek finishes and architectural elements that enhance any property. The open-span interior design eliminates the need for support columns, creating a true blank canvas that maximizes every square foot of usable space. Whether you're planning a workshop, starting a business, or creating your dream barndominium, these structures provide the flexibility to bring your vision to life.

Understanding the Value Proposition of Steel Structures

When you invest in a steel building, you're making a decision that pays dividends for decades. The value proposition extends far beyond the attractive initial price point - it's about creating a structure that works as hard as you do while keeping more money in your pocket over time.

Steel buildings deliver value through smart engineering and efficient manufacturing processes. The precision of pre-engineered components reduces waste and construction time, translating to direct savings for you. But the real value emerges over the life of your building. With minimal maintenance requirements and exceptional durability against weather, pests, and time, these structures continue saving money year after year. The adaptable design means your building can grow with your needs - whether that's expanding your business, adding living space, or reconfiguring for entirely new purposes. This flexibility, combined with steel's inherent strength and sustainability, makes it a smart investment that appreciates in value while serving your immediate needs.

What This Guide Will Cover About 30x40 Metal Building Prices

This comprehensive guide will walk you through everything you need to know about 30x40 metal building pricing in 2025. We'll explore the real costs involved - not just the sticker price, but the complete investment from foundation to finishing touches. You'll discover how different structural options, customization choices, and regional factors impact your budget, along with practical strategies to maximize value without compromising quality.

We'll also dive into the hidden costs that can catch buyers off guard, from permit fees to site preparation expenses. More importantly, you'll learn how to evaluate the long-term value of your investment, including energy savings, insurance benefits, and property value improvements. At National Steel Buildings Corp, we believe informed buyers make the best decisions, and this guide provides the knowledge you need to invest confidently in your 30x40 metal building project.

2025 Market Overview: Current 30x40 Metal Building Price Ranges

Ready to explore your 30x40 metal building options and get an accurate price quote?

Base Kit Price Expectations ($15-25 per Square Foot)

As discussed in our introduction, base kit pricing represents just one component of your total investment. At National Steel Buildings Corp, we've observed that 2025 base kits average $15-20 per square foot, reflecting the quality of commercial-grade steel I-beam frames manufactured to North American standards. These kits include your essential structural elements - columns, beams, trusses, and purlins - engineered specifically for your local load requirements.

The volatility in raw steel markets directly influences these base prices, with supply-demand dynamics creating opportunities for strategic timing. We guide our clients through these market fluctuations to optimize their investment. Remember, this base pricing covers only the manufactured components themselves - your complete project budget must account for foundation, delivery, and professional installation to ensure structural integrity and warranty protection.

Turnkey Installation Costs ($24-43 per Square Foot)

For complete turnkey solutions in 2025, expect comprehensive pricing between $24-43 per square foot. This investment encompasses everything needed for your finished structure - from engineered steel components to professional installation on a properly prepared foundation. Your 1,200 square foot building represents a total investment of $28,800-51,600, delivering exceptional value through our streamlined construction process.

Regional Price Variations Across the Country

Your building's location significantly shapes the final investment through various regional factors. Metropolitan markets naturally command premium labor rates, while rural installations benefit from lower overhead costs but may face transportation challenges. Distance from manufacturing facilities affects delivery expenses, typically adding $500-2,500 to your project budget depending on accessibility.

We engineer each structure to meet your specific regional requirements. Hurricane-prone coastal areas demand enhanced wind ratings and corrosion-resistant coatings, while northern climates require reinforced frames designed for substantial snow loads. These regional specifications, detailed further in our structural options section, ensure your building performs reliably in local conditions.

Market dynamics also influence regional pricing through contractor availability and local building department requirements. The Northeast and West Coast markets reflect higher regulatory standards and labor costs, while the Southeast and Midwest benefit from established steel building infrastructure and competitive installation markets. Understanding these regional variations helps you plan effectively and avoid unexpected costs during your project development.

How 2025 Market Conditions Are Affecting Steel Building Prices

The 2025 steel market presents both challenges and opportunities for building investors. Raw material volatility continues to influence component pricing, with supply chain dynamics creating windows for strategic purchasing decisions. At National Steel Buildings Corp, we monitor these market conditions daily to help clients optimize their timing and maximize value.

Beyond material costs, the current labor market significantly impacts project economics. Regions with established steel building expertise offer competitive installation rates and reliable scheduling, while areas with limited qualified crews may experience both higher costs and extended timelines. This reality underscores the importance of partnering with experienced providers who maintain strong installer networks.

Today's market conditions reinforce the wisdom of comprehensive project planning. Including appropriate contingencies for material fluctuations and potential site discoveries protects your investment timeline and budget. Our team guides you through these market dynamics, ensuring your project moves forward efficiently while maintaining the quality standards that protect your long-term investment.

Structural Options and Their Price Impact

Different structural options can significantly affect your total investment - which configuration best meets your needs?

Red Iron vs. Tubular Steel: Cost Comparison and Benefits

Red iron and tubular steel represent two distinct structural approaches with different cost implications. Red iron buildings use heavy I-beam steel frames that cost $20-40 per square foot, while tubular steel structures typically range from $15-30 per square foot[15]. Red iron's higher price reflects its superior load-bearing capacity, using structural-grade steels with yield strength up to 50 ksi that distribute weight through the frame rather than wall panels[16]. Tubular steel buildings utilize 12- or 14-gauge galvanized square or rectangular tubing, making them ideal for smaller spans like garages and workshops while offering faster installation times[16]. The core material composition remains similar - both use industrial-grade steel - but red iron features a distinctive iron oxide coating that provides additional rust protection and paint adhesion[15]. This coating contributes to higher maintenance requirements and costs compared to galvanized tubular steel, which offers better inherent moisture resistance[15]. When evaluating options, larger clear-span structures typically require red iron frames despite the higher cost, while smaller buildings can effectively utilize more economical tubular steel construction[15].

Clear-Span vs. Multi-Span Designs: Price Differences

Clear-span and multi-span designs represent fundamentally different structural approaches that impact both functionality and cost. Clear-span construction eliminates interior support columns, maximizing usable space while allowing cost-effective future expansions through load-bearing end walls[17]. This design typically costs 15-20% more than multi-span alternatives due to heavier structural components needed to support longer unsupported distances[18]. Multi-span designs incorporate interior columns to distribute loads more efficiently, reducing the size and cost of primary framing members. While this approach lowers initial material costs, it sacrifices flexibility in space utilization and future modifications[12]. The choice between these designs often depends on intended use - clear-span structures excel in applications requiring unobstructed floor space like workshops and equipment storage, while multi-span designs offer economical solutions for compartmentalized spaces such as office buildings or retail units[18]. Regional factors also influence this decision, as areas with high snow loads or strict seismic requirements may necessitate additional reinforcement in clear-span designs, further widening the cost differential[12].

Standard vs. Custom Engineering Considerations

The choice between standard and custom engineering significantly impacts 30x40 metal building costs. Standard designs follow a basic box configuration with simple gable or single slope rooflines at 4:12 pitch or less, and eave heights from 10' to 40', offering the most economical pricing through efficient engineering software processing[19]. Custom engineering becomes necessary for complex requirements like higher pitched roofs, extreme point loads, or specialized architectural elements, typically increasing costs by 15-20% due to additional structural calculations and materials[19]. A middle-ground 'modified standard' approach allows adding features like canopies, interior partitions, and various door configurations without altering the basic frame engineering, optimizing both functionality and budget[19]. Local building codes and weather conditions may necessitate custom engineering regardless of preference - areas prone to heavy snow loads or strict coastal requirements often demand specialized structural modifications that exceed standard design parameters[20]. The engineering choice ultimately affects both initial costs and construction timeline, with standard designs typically shipping faster while custom projects require extended engineering and fabrication periods[19].

Roof Systems and Their Cost Implications (Regular vs. Vertical)

Roof system selection significantly impacts both functionality and cost for 30x40 metal buildings. A-frame horizontal roofs, featuring panels arranged horizontally, offer a more budget-friendly option with straightforward installation and lower labor costs. However, these roofs can struggle with water drainage in areas with heavy precipitation[21]. Vertical roofs, while typically more expensive, provide superior protection through vertically arranged panels that create channels for efficient water, snow, and debris runoff. This design proves particularly valuable in regions with challenging weather conditions[21]. The choice between roof styles should consider local climate factors - vertical roofs excel in areas with frequent rain, snow, or storms, while horizontal roofs may suffice in milder conditions. Roof thickness also affects pricing, with standard 26-gauge steel panels being common, though upgrades to 24-gauge steel become necessary in regions with high winds and heavy snow loads[21]. The roof style selection ultimately impacts both initial costs and long-term maintenance requirements, making it crucial to balance upfront savings against durability needs[22].

Critical Cost Factors Beyond the Base Price

Understanding all cost components helps create a realistic budget - what factors matter most for your project?

Foundation Requirements and Site Preparation Expenses

Foundation requirements and site preparation represent critical cost components that significantly impact your total investment. A standard 4-inch concrete slab requires approximately 14.81 cubic yards of concrete and costs $9,600-12,000 installed, while upgrading to a 6-inch reinforced slab increases concrete volume to 22.22 cubic yards and pushes costs to $12,000-14,400. Beyond the slab itself, site preparation adds $1-1.25 per square foot, covering essential groundwork including soil grading, vegetation removal, and terrain leveling.

Understanding the unique foundation needs of metal buildings is crucial for proper budgeting. These lightweight structures require substantial foundations to resist uplift forces - think of them as huge sails that must be securely anchored against wind loads. Local conditions significantly impact both specifications and costs. Northern regions with deep frost lines often require specialized footings that can increase foundation expenses to $27,000 for a 30x40 structure, while areas with challenging soil conditions demand additional engineering solutions.

Professional foundation design from a licensed structural engineer ensures your building handles concentrated uplift and lateral loads properly. The foundation must extend below the local frost line and incorporate effective drainage systems to prevent moisture-related issues. Soil quality directly influences preparation needs - clay soils may require additional compaction or soil replacement, while rocky terrain necessitates specialized excavation equipment. At National Steel Buildings Corp, we help clients navigate these site-specific requirements during the planning phase, ensuring accurate budgeting from the start.

Insulation Options and Their ROI

Insulation packages for 30x40 metal buildings typically cost between $1,200-$3,300 total, averaging $1.00-$2.75 per square foot including materials and labor. Understanding insulation options helps you balance upfront costs with long-term value. Basic fiberglass insulation with polypropylene facing runs $0.50 per square foot for single-layer R13 systems, while double-layer R30 configurations reach $1.50 per square foot. Professional installation adds another $0.50-$1.25 per square foot during new construction.

This investment delivers impressive returns through multiple benefits. As mentioned in our long-term value analysis, properly insulated buildings save approximately $100 monthly in energy costs. Beyond the financial advantages, quality insulation creates a superior environment - reducing condensation issues, improving noise control, and maintaining comfortable temperatures year-round. Smart insulation choices paired with proper ventilation systems prevent moisture-related damage that can compromise your building's integrity.

Regional climate factors determine optimal insulation specifications. Buildings in extreme climates or snow-heavy regions require enhanced thermal protection, while structures in moderate zones can achieve excellent performance with standard insulation packages. We guide clients through selecting the right insulation strategy for their specific location and intended use, ensuring maximum return on this critical investment.

Doors, Windows, and Access Points: Pricing Breakdown

Door and window selections significantly impact both functionality and final costs of your metal building project. Understanding these options helps you make informed decisions that balance immediate needs with long-term value. Standard door packages include basic walk-in doors and roll-up garage doors, while premium options offer insulated doors, automatic openers, and enhanced security features that improve daily operations.

Window choices range from basic framed openings to energy-efficient glazing systems. Each opening requires specific engineering considerations to maintain structural integrity - the more openings you add, the more structural reinforcement your building needs. This relationship between openings and engineering requirements directly influences your total project cost.

Strategic planning of access points maximizes functionality while controlling expenses. Premium insulated doors and windows, though requiring higher upfront investment, often deliver superior performance through better climate control and enhanced durability. A critical design consideration: maintain a two-foot gap between the eave and the top of your tallest door. For instance, a 10-foot door requires a 12-foot eave height. Our team helps clients optimize door and window placement to achieve the perfect balance of functionality, aesthetics, and budget efficiency.

Finishing Touches: Interior Buildout Costs for Different Applications

Interior buildout costs vary significantly based on your intended use, making early planning essential for accurate budgeting. Basic finishing costs range from $35 to $110 per square foot beyond the shell assembly, encompassing essential elements that transform your steel structure into a functional space. Understanding these costs helps you prioritize features that deliver the most value for your specific application.

Standard interior components break down into manageable categories: drywall installation at $1.50-$3.50 per square foot, spray foam insulation at $1.00-$4.50 per square foot, and flooring options ranging from $4-$15 per square foot. For residential conversions like barndominiums, budget for kitchen installations ($4,500-$15,000 for cabinets, $50-$150 per square foot for countertops), bathroom fixtures, and HVAC systems ($7,000-$16,000 with ductwork).

Commercial applications offer more flexibility in finishing specifications. The base steel structure serves as a blank canvas, ready for customization through strategic interior partitions, specialized ventilation systems, and purpose-specific layouts. A crucial budgeting insight: interior buildout typically represents about 70% of your total project investment, with the exterior shell and assembly accounting for the remaining 30%. This ratio helps establish realistic expectations - while the steel building kit provides exceptional value, transforming it into your desired space requires careful financial planning.

Hidden Costs and Budget Planning

Proper budget planning prevents surprises - have you considered all potential costs for your project?

Permit Fees and Local Building Code Requirements

Understanding permit requirements early in your planning process can prevent frustrating delays and unexpected expenses. For a 30x40 metal building, permit costs typically range from $500 to $2,000, though commercial applications often face different fee structures - sometimes calculated at $0.15 to $0.84 per square foot. This means your 1,200 square foot structure could require permit investments anywhere from $180 to over $1,000, depending on local regulations.

Each jurisdiction maintains unique building codes that directly impact your project. Commercial structures face particularly stringent requirements due to public access considerations, often requiring detailed site plans and specialized evaluations. Beyond initial permit fees, budget for inspection costs that can add $100-$500 to your total investment. The key to avoiding costly delays? Start the permit process early and work with experienced professionals who understand local requirements. Consider factoring in potential costs for zoning variances or specialized inspections that your specific site might require.

Delivery Charges and Timeline Considerations

While base building costs are relatively predictable, delivery charges can surprise unprepared buyers. These fees typically range from $500 to $2,500, determined primarily by your distance from manufacturing facilities and site accessibility challenges. Remote locations or sites requiring special equipment access naturally incur higher delivery costs.

Timing plays a crucial role in both cost and scheduling. As discussed in our market overview section, booking during off-peak months like late fall or winter often yields better pricing and faster turnaround times. Peak construction seasons can extend typical 1-2 week delivery windows to 4-6 weeks or longer.

Your foundation must be ready when materials arrive - this critical coordination point trips up many first-time buyers. Weather delays, permit issues, or site preparation problems create costly domino effects throughout your project timeline. Working with an experienced team helps anticipate these challenges and build appropriate buffer time into your schedule.

Contractor vs. DIY Installation Cost Analysis

The installation decision - professional versus DIY - significantly impacts both your budget and project success. As covered in our pricing overview, professional installation adds $5-15 per square foot to your investment, but this expense often proves worthwhile for most buyers.

DIY installation might seem attractive for saving on labor costs, but consider the full picture: specialized equipment rentals alone can reach $2,000-$4,000, and your project timeline doubles from the typical 2-3 weeks to 4-6 weeks or longer. More critically, improper installation risks voiding manufacturer warranties and creating structural issues that cost far more to remedy than initial professional installation.

The installation process demands precision at every step - from initial frame assembly through final weatherproofing. Professional crews bring not just equipment like cranes and lifts, but also the expertise to ensure proper load distribution and code compliance. This becomes especially crucial for buildings with complex features or challenging site conditions. Our team at National Steel Buildings Corp connects you with qualified installers who understand the intricacies of metal building assembly.

Future Maintenance and Operational Expenses

Looking beyond construction costs, metal buildings deliver exceptional long-term value through minimal maintenance requirements. Unlike traditional structures demanding constant upkeep, your annual maintenance investment averages just 2-3% of initial building costs - a fraction of what wood or masonry buildings require.

Your maintenance routine remains refreshingly simple: periodic inspections of seals and fasteners, repainting every 15-20 years (compared to 5-7 years for wood structures), and occasional gutter cleaning. This durability advantage compounds over decades, creating substantial savings that offset any higher initial investment.

Operational expenses tell an equally compelling story. The superior insulation and energy efficiency features discussed throughout this guide translate directly to lower monthly utility bills. Well-designed ventilation systems - incorporating ridge vents, wall louvers, and strategic airflow patterns - minimize HVAC demands while preventing condensation issues that plague other building types.

Additional savings often come from reduced insurance premiums, as carriers recognize steel buildings' inherent safety advantages. Security features like reinforced entry points and integrated monitoring systems further protect your investment while potentially qualifying for additional insurance discounts.

For coastal or harsh-environment installations, specialized coatings and corrosion-resistant components require periodic attention but dramatically extend building lifespan. This targeted maintenance approach ensures your structure continues performing optimally for decades, validating the wisdom of choosing steel construction.

Strategic Savings Tips for Your 30x40 Metal Building Purchase

Strategic planning can save thousands on your building investment - which approach works best for you?

Timing Your Purchase: Seasonal Price Fluctuations

Strategic timing of your metal building purchase can yield significant savings throughout the year. Winter months present particularly advantageous conditions, as decreased construction activity creates opportunities for better pricing and faster project completion. During these off-peak periods, manufacturers often provide incentives to maintain steady production flow, translating into cost savings of 15-20% compared to busy spring and summer months. As discussed in our delivery timeline considerations, this seasonal strategy allows you to secure materials at optimal rates while benefiting from increased manufacturer attention and reduced lead times. At National Steel Buildings Corp, we help clients leverage these timing advantages by coordinating winter purchases for spring construction starts, ensuring you have ample time for permits and site preparation while locking in favorable pricing.

Negotiation Strategies When Getting Multiple Quotes

Securing the best value for your 30x40 metal building requires a strategic approach to gathering and evaluating quotes. Begin by requesting detailed breakdowns that separate materials, labor, permits, and additional services - this transparency helps identify opportunities for cost optimization without sacrificing quality. When comparing proposals, look beyond bottom-line pricing to evaluate what's included in each quote, ensuring you're making true apples-to-apples comparisons. Our clients often find that the lowest initial quote may exclude critical elements like proper insulation, necessary structural upgrades, or warranty protection. Leverage competition among suppliers by sharing your requirements clearly and asking for their best value proposition. Remember, reputable manufacturers welcome price discussions when they understand your complete project scope and timeline. Focus negotiations on areas with the most flexibility - delivery scheduling, payment terms, and included accessories often provide more negotiation room than base structural components.

Value-Engineering Without Compromising Quality

Value engineering represents a cornerstone of smart metal building investment, focusing on optimizing every aspect of your structure without compromising quality or functionality. This approach begins with strategic design decisions - proper spacing of structural members, selecting appropriate steel gauges for your specific needs, and utilizing pre-engineered components where they make sense. Our engineering team excels at identifying these opportunities, transforming complex requirements into clean, efficient designs that maximize both functionality and visual appeal. Modern tools like 3D modeling and Building Information Modeling (BIM) allow us to visualize your project comprehensively, identifying potential cost savings before construction begins. Strategic decisions about insulation placement, ventilation systems, and natural lighting integration create buildings that not only cost less initially but continue delivering savings through reduced energy consumption. The key lies in understanding that value engineering isn't about cutting corners - it's about making intelligent choices that align with your specific usage requirements while optimizing your investment for long-term performance.

Tax Incentives and Financing Options to Reduce Overall Costs

Smart financing strategies can significantly reduce the true cost of your 30x40 metal building investment in 2025. Business owners particularly benefit from Section 179 of the IRS Tax Code, which allows immediate deduction of up to $1,160,000 for qualifying metal building purchases in the year the property enters service - a substantial advantage over traditional decades-long depreciation schedules. The Modified Accelerated Cost Recovery System (MACRS) provides additional opportunities for accelerated depreciation, front-loading tax benefits when they matter most to your cash flow. While bonus depreciation provisions are phasing down, they still offer meaningful benefits for 2025 purchases. Energy-efficient metal buildings open doors to further savings through federal tax credits under Section 45L, potentially adding $2,000 per unit when meeting specific efficiency standards. State and local incentives often sweeten the deal through property tax abatements, sales tax exemptions on materials, and infrastructure development credits. Our team helps clients navigate these opportunities, ensuring you understand both immediate tax advantages and long-term operational savings. Remember, these benefits require proper documentation and business use intent, making professional guidance essential for maximizing your investment's financial efficiency.

Application-Specific Price Considerations

Different applications require unique features - how will you use your 30x40 metal building?

Residential Applications: Barndominiums and Shop Houses

The 30x40 metal building has emerged as a versatile residential solution, particularly for barndominiums and shop houses that maximize the 1,200 square feet of adaptable space. The inherent flexibility of steel construction allows this footprint to transform based on specific needs, from cozy family homes to combined living and working environments. Modern metal building homes benefit from higher ceilings than traditional construction, creating an enhanced sense of spaciousness while the column-free interior span provides a true blank canvas for layout optimization. For two-bedroom configurations, the space efficiently accommodates an open floor plan with strategic bedroom placement that maintains privacy while creating a versatile home office that doubles as a guest room when needed. Beyond the cost advantages discussed in our market overview, residential applications benefit from steel's exceptional design versatility. Barndominiums can be customized to mimic conventional wooden barn aesthetics while providing superior durability and minimal maintenance requirements. The design flexibility supports various interior finishing options, from exposed wooden beams and built-in shelving to decorative trim work that breaks up linear geometry while adding personality to each space. Our experience shows that residential metal buildings particularly excel when homeowners embrace the open-concept possibilities unique to steel construction.

Commercial Building Price Factors

Commercial applications of 30x40 metal buildings require careful consideration of several unique price factors beyond the standard costs outlined earlier. Commercial buildings face stricter requirements due to public access, necessitating additional engineering considerations and specialized features that impact overall costs. Local building codes significantly influence commercial specifications - areas with heavy snowfall may require 50 psf certification, while hurricane-prone regions demand thicker 26-gauge sheeting instead of standard 29-gauge materials. The commercial certification process differs substantially from residential, often requiring detailed site plans and specialized inspections, with permit fees ranging from $0.15 to $0.84 per square foot specifically for commercial structures. For optimal commercial functionality, these buildings require strategic customization with specific door configurations, ventilation systems, and interior partitions tailored to business operations. Commercial applications typically benefit from premium features like enhanced insulation and climate control systems that improve long-term operational efficiency. Our team helps commercial clients navigate these requirements while identifying opportunities to optimize both functionality and budget through smart design choices.

Agricultural and Storage Building Cost Optimizations

Agricultural and storage applications of 30x40 metal buildings benefit from several key cost optimizations unique to these uses. The clear-span advantages detailed in our structural options section become particularly valuable for equipment storage, while the load-bearing end walls enable cost-effective future expansions - extending length by 20 feet requires simply adding a frame line. For operations requiring compartmentalized spaces, strategic use of interior support columns can reduce costs while maintaining functionality. Smart design choices specific to agricultural use include optimizing roof pitch for your region - standard 1:12 pitches work well in most areas, though snow-heavy regions benefit from steeper 4:12 pitches for proper drainage. These structures excel at accommodating future growth through forward-thinking design that maintains structural integrity even when expanding to triple the original size. Agricultural buildings particularly benefit from strategic space planning - careful assessment of current equipment sizes, workflow patterns, and future expansion needs enables optimization of dimensions, height, and door placement. This application-focused approach ensures your building serves both immediate needs and long-term operational goals while maximizing value.

Garage and Workshop Specific Pricing Elements

Garage and workshop applications of 30x40 metal buildings require specific considerations that differentiate them from basic storage structures. Workshop configurations often demand the upgraded 6-inch reinforced concrete slabs discussed in our foundation section, essential for supporting heavy equipment, vehicle lifts, and machinery vibration. Beyond standard features, workshops benefit from strategic upgrades like insulated overhead doors with automatic openers, enhanced security systems, and specialized ventilation systems that prevent moisture damage to tools and equipment. Critical workshop-specific elements include reinforced mounting points for equipment, adequate electrical service planning for high-demand tools, and strategic placement of natural light sources to reduce eye strain during detailed work. The 30x40 footprint works particularly well for combination garage-workshop spaces, allowing distinct zones for vehicle storage and active work areas. Proper ventilation design becomes crucial in workshop applications - ridge vents combined with wall louvers create the airflow necessary to manage fumes, dust, and temperature control. These application-specific requirements, while adding to initial investment, create functional spaces that enhance productivity and protect valuable equipment investments over the building's lifetime.

Long-Term Value Analysis

Metal buildings deliver exceptional ROI through multiple channels - ready to explore the long-term benefits?

Durability and Lifecycle Cost Advantages

Metal buildings deliver exceptional lifecycle value through multiple durability advantages. At National Steel Buildings Corp, we've observed that properly constructed steel structures require minimal maintenance compared to traditional construction, with annual costs averaging just 1% of the initial investment versus 2-4% for wood and concrete buildings. This translates to $1,500-2,500 in yearly maintenance for a 10,000 square foot metal structure, while traditional buildings often demand $7,000-20,000 annually for repairs, painting, and replacements.

Steel's inherent resistance to pests, rot, moisture damage, and extreme weather conditions eliminates many common maintenance issues that plague traditional materials. We've seen wood-frame buildings in termite-prone regions face unexpected $30,000 damage repairs - costs that steel building owners simply avoid. The pre-engineered nature of our metal buildings creates significant upfront savings through precise material specifications that eliminate waste, while the high strength-to-weight ratio reduces overall material requirements.

Over a 20-year period, metal buildings maintain their value exceptionally well. Our clients frequently report resale value increases of 20-30% beyond standard property appreciation. The modular design allows easy expansion or modification for future needs, making these structures particularly attractive to future buyers. When you factor in reduced initial costs, lower energy expenses, and compounded value appreciation, the combined savings often reach $40,000-100,000 over the building's lifecycle.

Energy Efficiency Benefits and Utility Savings

Metal buildings deliver substantial energy savings through advanced insulation and design features. A properly insulated 30x40 structure can save approximately $100 monthly in utility costs, translating to $24,000 in energy savings over 20 years. Our cool metal roofing systems reflect solar radiation rather than absorbing it, reducing cooling costs by 10-25% compared to traditional roofing materials. Strategic insulation placement, combined with proper ventilation design, creates buildings that maintain comfortable temperatures year-round while minimizing HVAC demands. The tight construction tolerances of pre-engineered metal buildings eliminate air infiltration issues common in traditional construction, further enhancing energy efficiency. When paired with modern LED lighting and energy-efficient HVAC systems, these structures often achieve 40-50% lower operational costs than comparable traditional buildings.

Insurance Premium Reductions

Steel buildings earn substantial insurance premium reductions compared to traditional construction, with rates typically 30% lower due to their superior durability and fire resistance. This favorable pricing stems from insurance companies' classification systems - most steel structures qualify as Class 3 'noncombustible' buildings, reflecting their inherent resistance to common property damage risks.

The savings compound through multiple factors that we emphasize in our building designs. Steel structures demonstrate superior resistance to the leading causes of insurance claims, including water damage, hail impacts, and wind damage. With Class IV level UL 2218 Impact Resistance ratings, our engineered buildings withstand severe weather conditions, including winds up to 170 mph in properly designed structures.

The non-combustible nature of steel significantly reduces fire risks, while natural resistance to termites, mold, and moisture damage eliminates issues that average $3,000 annually in traditional buildings. Insurance providers particularly value steel buildings' comprehensive protection against catastrophic risks. In coastal regions where extreme weather typically drives 10-20% premium increases for traditional structures, steel buildings maintain more stable, lower rates.

To maximize these insurance advantages, we recommend documenting your building's safety features thoroughly. Additional protections like sprinkler systems, smoke alarms, and security features can further reduce premium costs while enhancing overall building value.

Property Value Impact Assessment

Metal buildings deliver exceptional returns on property value through multiple financial advantages. Market data consistently shows that metal structures, particularly garages, can increase overall property values by approximately 13%. A typical two-car steel garage can generate up to $30,000 in added property value - often delivering 2-2.5 times the initial investment.

Banks and appraisers classify pre-engineered metal buildings as permanent structures due to their engineered foundations and professional design standards. This classification makes them valuable assets for both financing and property assessments. At National Steel Buildings Corp, we ensure every structure meets or exceeds these professional standards, protecting your investment value.

The adaptability of steel structures enhances their investment potential significantly. A 30x40 building can transform between various uses - rental units, home offices, or recreational spaces - with proper interior finishing. This flexibility appeals to future buyers and maintains strong resale values as market needs evolve.

Beyond direct property appreciation, the operational savings discussed earlier compound your returns. When you combine property value increases with energy savings of approximately $100 monthly and insurance premium reductions of up to 30%, the financial advantages become compelling. The Insurance Services Office (ISO) classification of most steel buildings as Class 3 'noncombustible' structures further validates their value proposition, balancing excellent fire protection with cost-effectiveness. This comprehensive combination of property appreciation, operational savings, and reduced insurance costs creates returns that extend well beyond the initial construction investment.

Buyer's Guide: Avoiding Common Pitfalls

Avoid costly mistakes by knowing what to look for - are you prepared to evaluate building quotes effectively?

Red Flags When Evaluating 30x40 Metal Building Quotes

When evaluating 30x40 metal building quotes, watch for deceptively low prices that seem too good to be true - these often indicate compromised quality through substandard materials like 2-inch tube steel and 29-gauge sheeting that won't meet local building codes. Be wary of companies pushing for quick, non-refundable deposits before providing detailed specifications or engineering drawings. Scrutinize any supplier claiming to have "cancelled orders" available at discounts or promising unusually fast delivery times, as these are common telemarketing tactics. Verify the legitimacy of metal building companies by checking their physical business address - legitimate suppliers openly display their location while questionable ones often hide behind mailbox stores or strip-mall addresses. Research the company's business license status and duration of operation, as warranty promises mean little from recently established firms. High-pressure sales tactics like "this deal ends today" or aggressive callback campaigns should raise immediate concerns. Watch for bait-and-switch pricing where advertised rates only apply to specific regions or basic configurations, with substantial markups for necessary upgrades like insulation, windows, and doors.

Understanding Warranty and Guarantee Terms

Metal building warranties in 2025 have evolved to provide multi-tiered coverage reflecting manufacturer confidence. Structural warranties typically span 25-50 years, protecting frame systems against material and workmanship defects, while paint and panel finishes carry 10-20 year coverage against issues like fading and adhesion failure. Modern warranty packages include rust-through protection for serious corrosion that perforates steel, paint warranties for coating integrity, and workmanship coverage when installed by manufacturer crews. Maintaining warranty validity requires following specific maintenance protocols - skipping recommended cleaning, using unapproved installers, or making unauthorized modifications can void coverage. The warranty landscape has shifted notably in 2025, with improved paint coverage due to advanced UV-resistant coatings and enhanced corrosion protection for coastal environments. However, warranties explicitly exclude damage from natural disasters, vandalism, and third-party modifications. When evaluating coverage, examine specific terms rather than just warranty length - comprehensive support and clear documentation demonstrate manufacturer commitment to long-term customer satisfaction. Quality manufacturers of commercial-grade steel buildings stand behind their products with transparent warranty terms and accessible customer service.

Vetting Manufacturers and Installers

Selecting qualified manufacturers and installers requires evaluating multiple key factors in 2025's metal building market. As discussed in the installation cost analysis section, professional teams complete assembly within 2-3 weeks using specialized equipment while ensuring code compliance. The volatile steel market demands close attention during manufacturer selection - as noted in our market overview, steel prices have experienced significant fluctuations, making timing and supplier stability crucial. Smart project planning includes verifying that installers maintain proper documentation and structured completion checklists, as studies show that rework can account for approximately 5% of a project's total value. The most effective installers utilize comprehensive checklists that unify all vital build phases - structural framing, sheeting and trim, weatherproofing, accessory installation, and final job site cleanup - into a systematic verification process. When evaluating manufacturers, verify their physical business address and duration of operation, as warranty promises mean little from recently established firms. Established suppliers provide transparent pricing, detailed specifications, and proven track records of successful installations across diverse applications.

- https://www.empirebuilt.com/30x40-metal-building/

- https://www.architecturecourses.org/build/prefab-metal-building-prices

- https://armstrongsteel.com/top-metal-building-design-trends-to-watch-in-2025/

- https://bulldogsteelstructures.com/blog/the-ultimate-guide-to-building-a-30x40-metal-structure-costs-design-and-more/

- https://prometalbuildings.com/metal-building-cost-2025/?srsltid=AfmBOoqGVcvIE463kTFPkPundiCY4Hj5AMPWCWA0YX2wvEVfTYbpmfLK

- https://pricebuildings.com/steel-buildings/cost/30x40-metal-building-cost/

- https://www.buildingsguide.com/metal-building-prices/?srsltid=AfmBOoq_7U39tBrpKzLSipnyMdKtmCwHm9byoRS2Ohdlt1CtJmOTUIRM

- https://directmetalstructures.com/blog/how-much-does-a-30x40-metal-garage-cost-in-2025-price-factors-you-should-know/?srsltid=AfmBOorSrUixr_HasGt0qIS8vFI32EitLaCsewycqCj5adJeb-NRLnlJ

- https://www.buildingsguide.com/metal-building-prices/?srsltid=AfmBOorpejlSiLVH96Aw-v8D-mNbTtlVMr_X5xKv8CeTltJijYOzb7nt

- https://homeguide.com/costs/metal-building-cost

- https://www.buildingsguide.com/metal-building-prices/?srsltid=AfmBOorptfQVJhhLZtU-dy_Ncc4ev0UOkKjUZ1J-3OMe0v_2Rru-3eiR

- https://nationalsteelbuildingscorp.com/blog/how-much-does-a-30x40-metal-building-with-slab-cost/

- https://www.aametalbuildings.com/blog/metal-garage-prices-explained-everything-you-need-to-know-before-buying?srsltid=AfmBOopr8A74bS0egYEZ4Eh5CQQkG4mohQ3NRmKP6La6LeEbv-umxc6f

- https://www.buildingsguide.com/metal-building-prices/?srsltid=AfmBOoopxlRjg1Hy49Yf4SAWI9UtSeHykxvAT8jEc7cmPzDpbdsQ7jwb

- https://alansfactoryoutlet.com/blog/red-iron-steel-building/?srsltid=AfmBOopMq1876luMGn-TWwY_2mXtisgSDSXrIpCqu7dfNrvIRAjQ8n5x

- https://americanmetalgarages.com/red-iron-vs-pole-barn-vs-tubular-frame-cost-lifespan-best-uses/

- https://www.buildingsguide.com/metal-building-prices/?srsltid=AfmBOoqXntULpELdKZMWuihJ2BHEDD5NJ9gwmSV3hSqbbPzUgtB4KO9Y

- https://americansteelinc.com/blog/steel-building-costs-prices-guide/

- https://www.rhinobldg.com/blog/standard-or-custom-steel-buildings

- https://titansteelstructures.com/facts/how-much-does-a-30x40-metal-building-cost/

- https://www.bossbuildings.com/building-comparisons/comparison-between-horizontal-and-vertical-roof-metal-buildings/?srsltid=AfmBOop64s0u6mt8SFk9g9W-zFj-jJL6p4bv1NcoEZ0uy0VSlVafuIas

- https://alansfactoryoutlet.com/metal-building-prices/?srsltid=AfmBOopFT8SgqX-kX9NvUvoBPjMWAXBRe3Np8kgqaGofgbBzOqm7rusY

- https://www.buildingsguide.com/build/metal-building-foundations/?srsltid=AfmBOooJGX2NEpdI9bErDxH_tzK7NdrTpQSFk1LSMhv8wuBNw6OXOyrP

- https://steelbuildinginsulation.com/insulate-30x40-metal-building/

- https://www.buildingsguide.com/standard-sizes/30x40-metal-building/?srsltid=AfmBOopdY1Wn4mcgVg8_vWOccDR26atYKc4e6GQI6-r4fM1eYA5t5sw9

- https://homeguide.com/costs/metal-building-homes-cost

- https://www.buildingsguide.com/standard-sizes/30x40-metal-building/?srsltid=AfmBOop31Go4-dFmlWFpvlM7AsbtVviqr2vTPuJOF2iADRv4eoZe1DW4

- https://www.mysiteplan.com/blogs/news/building-permit-costs?srsltid=AfmBOopdXLqVGpnubTjYxyRNaWsoBrx7XrCa3AhXKwo-5YFLrX2Yho21

- https://prometalbuildings.com/metal-building-cost-2025/?srsltid=AfmBOoo_2jLHDsCm5s-LBAgbPDj7G_W6Q3w7CgbbzDtQ4ahJV3raHVVP

- https://www.buildingsguide.com/metal-building-prices/?srsltid=AfmBOorA4eb1PdEaVUpExzsT82fncqPKRC8eTHkDMstp2dswtiUJaaOZ

- https://www.uspatriotsteel.com/blog/how-much-does-a-30x40-metal-building-cost/

- https://metalbuildingsnorthamerica.com/30x40-metal-building-construction-facts/

- https://steelarchbuildings.com/when-is-the-best-time-to-buy-metal-buildings/

- https://www.futurebuildings.com/blog/winter-deals-on-steel-buildings.html

- https://www.metalbuildingoutfitters.com/5-best-tips-for-estimating-metal-building-costs/

- https://www.steelcobuildings.com/metal-building-cost-a-comprehensive-guide-to-budgeting-and-planning/

- https://www.metalbuildingoutfitters.com/budgeting-tips-for-metal-building-costs/

- https://www.aegismetal.com/newsView,130,value-engineering-in-metal-building-construction-cutting-costs-not-corners,EN

- https://canyonbd.com/7-ways-value-engineering-saves-money/

- https://www.paramountmetalsystems.com/tax-advantages-of-metal-building-systems-save-money-while-adding-value

- https://americancarportsinc.com/blog/metal-building-business-taxes/

- https://nationalsteelbuildingscorp.com/blog/30x40-metal-building-home-floor-plans-design-guide-duplicate/

- https://nationalsteelbuildingscorp.com/blog/30x40-metal-building-home-floor-plans-design-guide/

- https://www.buildingsguide.com/metal-building-prices/?srsltid=AfmBOoq1cFuEizgJ0twxrwjLugYPQVratMsF-RWHMbQqU8vI15wqWJbA

- https://gensteel.com/building-faqs/steel-building-prices/cost-to-build-barndominium/

- https://www.buildingsguide.com/metal-building-prices/?srsltid=AfmBOorUCpQYJ5zgk3Q3yJXCucvhh7ASvR68eHKSxXYng46BVsvQE2wR

- https://directmetalstructures.com/blog/how-much-does-a-30x40-metal-garage-cost-in-2025-price-factors-you-should-know/?srsltid=AfmBOoq4lTKTEow2g06ocINIeEbdlHAz1R56clQI6l1GMwdK00r1Yq0B

- https://alansfactoryoutlet.com/metal-building-prices/?srsltid=AfmBOooXavR1J_2RkrJEY1ycN9VOCEkrKVvxwvQXyE-vVuyvncP8qFiH

- https://directmetalstructures.com/blog/how-much-does-a-30x40-metal-garage-cost-in-2025-price-factors-you-should-know/?srsltid=AfmBOoq6j7gqjvLbsg3_I0GbniXpfm_UYs3By57itwYvF2fo7eUtIx4k

- https://www.summitsteelbuildings.com/20-year-cost-comparison

- https://miracletruss.com/why-metal-buildings-can-decrease-the-cost-of-your-insurance-premium/

- https://www.peaksteelbuildings.com/is-insurance-cheaper-for-a-steel-building/

- https://dreamhomeinnovate.com/17900-steel-building-heres-what-theyre-not-telling-you/

- https://www.bucksteel.com/blog/metal-buildings/metal-building-scams-the-telemarketers/

- https://garagebuildings.com/steel-building-warranties-explained-whats-really-covered-in-2025-2026

- https://www.junnansteelstructure.com/blog/future-of-metal-buildings-2025-key-trends-checklist/

- https://www.tylerbuilding.com/post/the-metal-building-checklist-that-protects-your-margins

- https://metalprobuildings.com/your-metal-building-buyers-final-checklist-7-steps-before-you-order/

- https://www.buildingsguide.com/build/30x40-building-construction/?srsltid=AfmBOoqMqHXI2kC25twKhTyP4wZhbOkwaQX4mzhXhzRrXGr_u89c7eR3