How Much Does a Warehouse Cost? Key Factors and Estimates

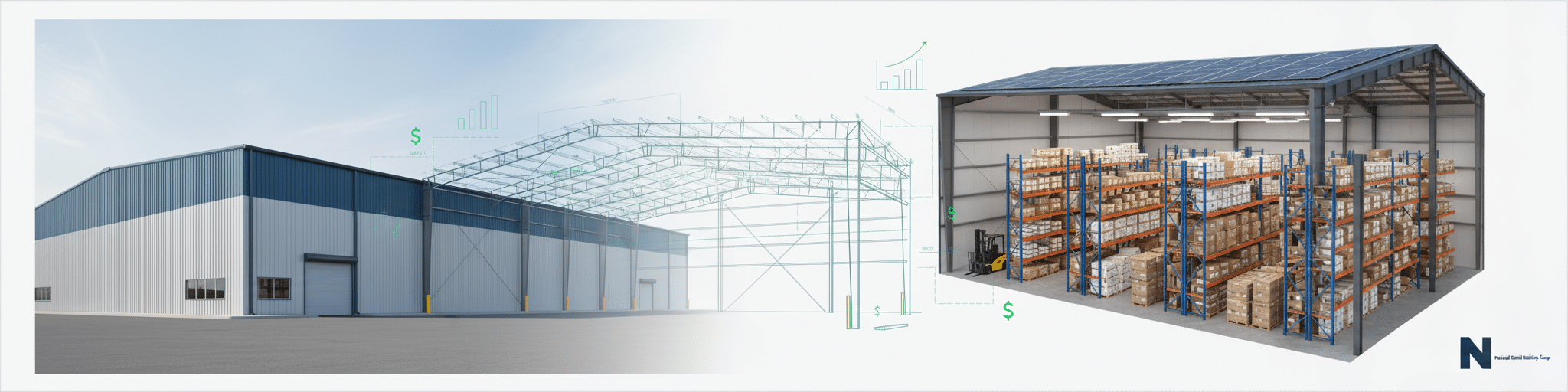

This comprehensive guide explores warehouse construction costs and factors affecting pricing in 2024-2025. Learn about current cost estimates ranging from $20-60 per square foot, regional variations, construction methods including pre-engineered metal buildings and steel frame options, and financial planning strategies. Discover how location, size, materials, and technology choices impact your total investment, with practical insights for creating budgets and maximizing ROI on warehouse projects from 5,000 to 100,000+ square feet.

Introduction

How is the e-commerce boom reshaping warehouse investment strategies for 2024-2025?

The Strategic Importance of Warehouse Investment in Today's Market

Warehouse investment has become increasingly critical as ecommerce continues its dramatic growth trajectory, with online sales projected to exceed 20% of all retail purchases for the first time in 2024 [1]. This shift is driving unprecedented demand for warehouse space, particularly as consumer expectations for rapid fulfillment intensify - 99% of retailers now plan to offer same-day delivery by 2025 [1]. The pressure to optimize warehouse operations is further amplified by ongoing supply chain disruptions, with 87% of businesses experiencing disruptions in the past year [2]. In response, organizations are making strategic investments in warehouse technology and infrastructure, with 56% of companies directing capital toward advanced warehouse management systems, visibility tools, and transportation solutions [2]. The labor landscape adds another layer of complexity, as nearly 75% of operations cite attracting and retaining qualified workers as their primary challenge entering 2024 [1]. These converging factors make warehouse investment not just a logistical necessity, but a critical competitive differentiator in today's rapidly evolving market.

Recent Trends in Warehouse Construction (2024-2025)

Warehouse construction is showing signs of recovery after a 25% decline in new builds during 2023, with growth expected to resume in 2024-2025 as e-commerce stabilizes and companies embrace just-in-case inventory management [5]. The automation sector mirrors this trajectory, with orders projected to increase through 2024 and return to double-digit growth by 2025 [5]. Major retailers continue driving significant warehouse investments across key markets, pursuing strategic automation upgrades to meet evolving consumer demands [5]. Sustainability and technology integration are reshaping warehouse design, as 55% of industrial manufacturers now leverage generative AI tools in their operations [4]. Advanced robotics have evolved from optional to essential, delivering key benefits like greater efficiency, scalable operations, and improved workflow visibility [5]. Energy-efficient innovations, including automated storage and retrieval systems, are helping facilities reduce waste and emissions while cutting operational costs [5]. This technological transformation is supported by growing investment in data lifecycle management, with three-quarters of organizations increasing funding to support AI and automation strategies [5].

What This Guide Will Cover About Warehouse Costs

This comprehensive guide breaks down the essential factors affecting warehouse construction costs in today's dynamic market. We'll explore the four key cost components that shape your investment: hard costs, soft costs, contingency planning, and land acquisition [6]. You'll discover how different construction methods - from traditional steel frame to cost-effective pre-engineered metal buildings - impact your bottom line. We'll analyze current pricing trends, regional variations, and the latest material costs that influence project budgets. Beyond basic construction, we'll examine critical factors like site preparation, permitting requirements, and MEP system integration. The guide also covers financial planning strategies, including financing options and the build vs. buy vs. lease decision framework. Whether you're planning a 5,000 square foot distribution center or a 100,000 square foot logistics hub, this guide provides the insights needed to make informed decisions about your warehouse investment.

Current Warehouse Construction Cost Estimates

Pre-engineered metal buildings offer the most cost-effective warehouse solution at $20-35 per square foot.

Average Cost Per Square Foot Breakdown (2024-2025 Figures)

When planning your steel warehouse project, understanding current market pricing helps you make informed decisions about construction methods and materials. Pre-engineered metal buildings (PEMB) deliver the most cost-effective solution at $20-35 per square foot, making them an ideal choice for businesses seeking maximum value without compromising structural integrity. Our custom metal building design services help optimize these costs while meeting your specific operational needs. Tilt-up construction ranges from $40-55 per square foot, offering durability for projects requiring concrete walls and specific fire ratings. Traditional structural steel construction commands $45-60 per square foot, providing maximum flexibility for complex designs and multi-story facilities [8]. The average turnkey warehouse cost spans $20-60 per square foot when factoring in all components, with most projects falling in the $35-50 range [9]. These figures represent building shell costs including foundation and basic construction, but exclude interior build-out, specialized equipment, and site-specific requirements that can add substantially to your total investment.

Total Project Cost Ranges by Warehouse Size (5,000-100,000 sq ft)

Steel building costs scale efficiently as your facility size increases, offering predictable budgeting across various project scopes. A 5,000 square foot steel warehouse typically requires an investment of $100,000-175,000 when utilizing pre-engineered metal construction methods. This size suits many small businesses entering the warehousing sector or those needing dedicated storage space.

For growing operations, 20,000 square foot facilities range from $240,000-380,000, with final pricing influenced by your specific operational requirements and chosen steel building features. Distribution centers in the 50,000-60,000 square foot range command budgets of $750,000-1,000,000 using standard steel construction materials and essential features.

Large-scale operations approaching 100,000 square feet should plan for investments between $2-6 million, as outlined in our Introduction. This range reflects the spectrum from efficient pre-engineered steel systems to more complex designs incorporating advanced material handling infrastructure. Remember that these baseline figures cover the primary structure - your specific operational needs for racking systems, climate control, and workflow optimization will influence the final investment.

Regional Cost Variations Across the United States

Regional market conditions significantly impact your steel building investment, with construction costs varying up to 20% from national averages depending on location. Understanding these variations helps you make strategic decisions about facility placement and budget allocation.

The Pacific Northwest presents the highest costs, with Seattle commanding premium prices - $182 per square foot for smaller projects, decreasing to $98 for medium-scale facilities and $83 for large distribution centers. These elevated costs reflect both material availability challenges and intense competition for skilled construction professionals.

Conversely, Sun Belt markets offer compelling value propositions for steel building projects. As discussed in our Location Considerations section, Dallas and Houston provide particularly attractive economics, with total project costs running 15-20% below national averages. The South and Midwest regions benefit from proximity to steel production facilities and lower concrete pricing, creating favorable conditions for cost-conscious developers.

Labor availability remains a critical factor across all markets, with construction wages averaging $35.42 per hour nationally. Markets experiencing rapid growth, like Miami, have seen costs escalate as demand for skilled steel erectors and construction professionals intensifies. Strategic site selection balancing these regional cost factors with your operational requirements can yield substantial savings on your steel warehouse investment.

How Construction Costs Have Evolved Since 2019

The steel building industry has navigated significant cost pressures since 2019, with construction inflation running approximately 2.5 times the general Consumer Price Index growth rate. This unprecedented period saw total industrial construction costs surge 38% from pre-pandemic levels to peak, with building shell costs - the core of any steel structure - jumping 43%.

Steel pricing volatility particularly impacted facilities located far from major importing ports, where transportation costs compounded material expenses. However, the inherent efficiency of pre-engineered steel systems helped many projects maintain better cost control compared to alternative construction methods during this turbulent period.

By 2023, we observed stabilization in several material categories, though concrete costs continued their upward trajectory with an 8% increase - affecting foundation work across all construction types. Markets including Savannah, Nashville, Columbus, the Inland Empire, and Philadelphia experienced delayed but pronounced cost increases, primarily driven by concrete pricing that rose at nearly double the national average.

Supply chain challenges extended project timelines significantly, with material lead times stretching to two or three times normal duration. While roofing materials have largely returned to standard availability, electrical equipment and HVAC systems continue experiencing extended lead times. Planning for these realities, experienced steel building contractors help clients navigate material availability challenges while maintaining project momentum through strategic procurement and scheduling adjustments.

Primary Factors Affecting Warehouse Construction Costs

Strategic location selection can reduce operational costs by 20-30% over your warehouse's lifetime.

Location Considerations and Land Acquisition Expenses

Your warehouse location choice fundamentally shapes both construction and operational costs. We've seen prime locations near transportation hubs command premium prices, yet these investments often pay dividends through reduced shipping times and improved delivery speeds [12]. Understanding the urban versus rural trade-off is crucial - urban sites offer robust labor pools and infrastructure but require higher capital investment, while rural locations provide cost savings that may be offset by workforce recruitment challenges [13].

Construction costs vary dramatically by region, with port cities like Seattle commanding top dollar at $182 per square foot for smaller projects, while inland markets often deliver 15-20% savings [14]. Beyond raw land costs, savvy developers evaluate municipal incentive programs that can significantly offset initial investments [13]. Strategic positioning near your suppliers and customers creates ongoing operational savings that compound over time [12]. As e-commerce continues reshaping distribution networks, we're seeing unprecedented demand for facilities within 20 miles of population centers - a trend that's fundamentally altering warehouse real estate dynamics [13].

Size, Layout, and Specific Operational Requirements

Your warehouse's size and layout directly determine operational efficiency and long-term success. As discussed in the cost estimates section, modern facilities utilize clear spans of 24-34 feet, with automated systems pushing heights to 45+ feet for maximum vertical storage capacity [15]. Every layout decision impacts your bottom line - from choosing between traditional pallet racks and automated systems to strategically placing mezzanines that can double usable space without expanding your footprint [15].

Workflow efficiency requires careful planning to eliminate costly bottlenecks. Consider that walking represents over 50% of labor hours in typical distribution centers - proper design can dramatically reduce this waste [15]. Critical infrastructure like dock doors and staging areas deserve special attention. We recommend maximizing dock door configurations while maintaining 15-20% open floor space for smooth material flow [15]. Smart slotting strategies ensure your fast-moving inventory - typically 80% of unit sales - remains easily accessible in dedicated zones sized appropriately for each product category [15].

Material Selection and Quality Standards

Material selection drives both immediate costs and decades of maintenance expenses. As outlined in our construction cost estimates, structural materials comprise over 50% of shell construction costs, making informed choices critical to project success [7]. The current market presents both challenges and opportunities - while concrete costs have surged 8% recently, steel prices have stabilized, creating strategic advantages for projects utilizing pre-engineered steel building systems.

Quality standards extend beyond initial material specifications to encompass long-term performance factors. Premium galvalume steel roofing may cost 10-15% more than standard galvanized options, but delivers superior corrosion resistance and extended warranty coverage. Similarly, investing in high-grade insulation systems with R-values of 6.0 per inch reduces energy costs by 20-30% annually while preventing condensation issues that plague under-insulated facilities.

Labor Market Conditions and Contractor Selection

Today's tight labor market demands strategic planning, with skilled worker shortages affecting nearly 80% of construction projects globally [16]. As noted in our cost analysis, construction wages now average $35.42 per hour nationally, though regional variations create opportunities for cost optimization [7]. Premium markets like Seattle and Miami command top wages, while strategic locations in other regions offer competitive labor costs without sacrificing quality [7].

Contractor selection proves critical to project success. We've observed dramatic pricing variations even within single markets - identical project specifications can yield vastly different estimates based on each contractor's market position and workforce availability [7]. This underscores why partnering with experienced steel building specialists matters. Our established relationships with skilled trades and proven project management approach help navigate labor challenges while maintaining schedule and budget integrity. Early engagement allows us to leverage our network for competitive pricing and secure skilled workers before shortages impact your timeline [7].

Construction Methods and Their Cost Implications

Pre-engineered buildings reduce construction time by 30-50% compared to conventional methods.

Steel Frame Construction: Costs, Benefits, and Limitations

Steel frame construction delivers unmatched versatility for warehouse projects requiring sophisticated designs or specialized operational features. The structural steel framework provides exceptional clearspan capabilities, eliminating internal support columns to create expansive, adaptable spaces that evolve with your business needs. This construction method excels in durability - properly maintained steel structures serve operations reliably for 50-100 years, making them a sound long-term investment. Steel buildings also offer strategic advantages for future growth, as the framework accommodates modifications and expansions more readily than rigid concrete alternatives. Our structural steel components are engineered to optimize both strength and flexibility, ensuring your facility can adapt to changing market demands. While steel construction requires careful planning around electrical and HVAC integration timelines, the superior performance characteristics and operational flexibility justify the investment for facilities demanding maximum versatility.

Pre-Engineered Building Systems vs. Traditional Construction

Pre-engineered building systems represent the pinnacle of efficiency in warehouse construction, delivering exceptional value through precision engineering and optimized manufacturing processes. These systems achieve remarkable construction speed - typically 30-50% faster than conventional methods - because components arrive at your site ready for immediate assembly. The factory-controlled fabrication ensures consistent quality while minimizing material waste, translating to both cost savings and environmental responsibility. Pre-engineered systems excel for warehouse applications up to 30 feet in height, providing the ideal solution for distribution centers, manufacturing facilities, and storage operations prioritizing rapid deployment and budget control. For projects requiring unique architectural elements or complex multi-story designs, traditional construction methods maintain their place, offering unlimited customization possibilities. Understanding these trade-offs helps determine the optimal approach - pre-engineered systems dominate when speed, cost-efficiency, and proven performance drive decision-making, while conventional construction serves specialized requirements demanding complete design freedom.

Concrete Tilt-Up Construction Analysis

Tilt-up construction bridges the gap between economy and durability, combining concrete's strength with efficient construction techniques. This method involves casting concrete panels on-site and tilting them into position, creating robust exterior walls that excel in fire resistance and thermal mass properties. The construction approach particularly suits single-story warehouses where the benefits of concrete's durability align with operational requirements for temperature stability and minimal maintenance. Recent market dynamics have impacted tilt-up construction costs, particularly in markets experiencing concrete supply constraints. The South and Midwest regions maintain competitive advantages for this method due to favorable material availability and established contractor expertise. When evaluating tilt-up versus steel alternatives, consider factors beyond initial costs - concrete's thermal properties can reduce HVAC expenses in climate-controlled facilities, while steel structures offer superior modification flexibility for evolving operations.

Innovative Construction Technologies and Their ROI

Advanced construction technologies are revolutionizing how modern warehouses take shape, delivering quantifiable returns through enhanced precision and efficiency. Building Information Modeling (BIM) enables our teams to identify and resolve potential conflicts before breaking ground, while drone surveys provide real-time progress monitoring that keeps projects on schedule. The strategic integration of technology extends beyond construction into operational readiness - smart building systems, energy-efficient LED lighting, and IoT-enabled infrastructure create facilities prepared for tomorrow's automation demands. These innovations prove particularly valuable when combined with steel construction's inherent flexibility, allowing seamless integration of automated storage systems, robotics, and advanced material handling equipment. Energy efficiency stands at the forefront of modern warehouse design, with features like high-performance insulation, intelligent HVAC controls, and natural lighting strategies reducing operational costs while supporting sustainability objectives. Success in technology implementation requires careful evaluation of both immediate needs and future scalability - the most effective solutions balance current operational requirements with the flexibility to accommodate emerging technologies as your business evolves.

Additional Cost Considerations Beyond Basic Construction

Proper site preparation and foundation work can prevent 90% of future structural issues.

Site Preparation, Foundation, and Structural Requirements

Site preparation and foundation work form the cornerstone of any successful warehouse project, often accounting for unexpected budget variations. For facilities handling heavy rack loads exceeding 40,000 pounds, you'll need to allocate approximately $0.75 per square foot for each additional 2 inches of concrete thickness—a critical investment in structural integrity.

Foundation requirements vary dramatically based on your location and soil conditions. As discussed in our construction methods section, concrete costs have experienced significant regional variations, with Southern and Midwestern markets offering the most competitive pricing. When evaluating your site, consider that proper foundation work extends beyond mere cost calculations—it's about ensuring your facility can support your operational needs for decades to come.

The structural design of modern warehouses requires careful planning to maximize both efficiency and flexibility. While we covered optimal clear spans and building heights in our operational requirements section, it's worth emphasizing that your foundation must support not just today's needs but future expansions and equipment upgrades. Strategic foundation planning also includes maintaining adequate open space for material flow and implementing proper drainage systems to protect your long-term investment.

Permitting, Zoning, and Regulatory Compliance Expenses

Navigating the permitting and regulatory landscape represents a crucial investment in your warehouse project's success. Beyond the obvious requirement for building permits, you'll need comprehensive documentation including architectural drawings, detailed project plans, safety protocols, and environmental impact assessments. This upfront diligence pays dividends by preventing costly delays and ensuring smooth project progression.

The regulatory framework extends well beyond initial construction. Your facility must maintain ongoing compliance with an evolving web of local, state, and federal regulations. Environmental standards have become particularly stringent, encompassing air quality, water management, and waste handling requirements. These aren't mere bureaucratic hurdles—they're essential safeguards that protect your investment and maintain your reputation with increasingly compliance-conscious customers and partners.

For larger warehouse projects exceeding 200,000 square feet, the permitting complexity multiplies exponentially. Professional guidance becomes not just helpful but essential to navigate these requirements efficiently. The cost of expert assistance pales in comparison to potential fines, project delays, or—worst case—facility shutdowns that can result from non-compliance. Think of permitting expenses as insurance for your project timeline and operational continuity.

MEP Systems, Technology Integration, and Automation Costs

Modern warehouse MEP (mechanical, electrical, and plumbing) systems, along with technology integration and automation, have evolved from optional enhancements to essential competitive tools. Entry-level automation packages typically range from $50,000 to $500,000, while comprehensive systems for large-scale operations can require multi-million dollar investments. The key is selecting solutions that align with your operational goals and growth trajectory.

Today's warehouse technology landscape centers on integration and intelligence. Cloud-based warehouse management systems have become the industry standard, achieving 90% adoption rates while dramatically reducing operational errors. When combined with quality infrastructure components, these systems create facilities capable of adapting to evolving market demands. Predictive maintenance alone can reduce machine downtime by 30-40% while extending equipment lifespan by 20-40%.

The autonomous mobile robot (AMR) market exemplifies this technological transformation, growing at 17.5% annually with projections reaching $4.1 billion by 2028. Smart building features—from automated climate control to IoT-enabled security systems—no longer represent futuristic concepts but practical investments that deliver measurable ROI through reduced labor costs and improved operational efficiency.

Sustainability Features and Their Long-Term Value

Sustainability has transformed from a nice-to-have feature into a powerful value driver for warehouse investments. Green-certified facilities now command significant market premiums—19% in prime locations and up to 24% in secondary markets—reflecting strong demand from environmentally conscious tenants and investors. These premiums represent just the beginning of sustainability's financial benefits.

The business case for green warehouse features is compelling and quantifiable. Every $13 per square meter invested in sustainability improvements typically reduces CO2 emissions by 2.2 kg annually, with average payback periods of 7.5 years. But the benefits extend far beyond direct cost savings. Modern sustainable warehouses incorporating renewable energy systems, advanced eco-friendly building materials, and intelligent resource management create facilities that attract premium tenants, reduce operational costs, and maintain higher asset values over time.

Energy efficiency initiatives deliver particularly strong returns. LED lighting with occupancy sensors, high-performance insulation achieving R-values of 6.0 per inch, and smart HVAC systems can reduce energy consumption by 30% or more. Water conservation measures—including rainwater harvesting and greywater recycling—further reduce operational expenses while demonstrating environmental stewardship that resonates with stakeholders across your supply chain.

Financial Planning for Warehouse Development

Smart financial planning can reduce your total warehouse investment by 15-25%.

Creating a Comprehensive Warehouse Construction Budget

Creating a comprehensive warehouse construction budget starts with understanding the key cost components outlined in earlier sections. As we've discussed, the typical breakdown includes hard costs, soft costs, and contingency reserves, but successful financial planning goes beyond these basics. When developing your budget, consider both immediate construction expenses and long-term operational costs that will impact your total investment.

For effective budget planning, begin by establishing clear project objectives and specifications. The size, location, and intended use of your warehouse will drive most financial decisions. Remember that while initial construction represents the largest expense, annual operating costs for utilities, maintenance, and security can significantly impact your long-term financial picture. A well-planned budget accounts for both phases of ownership.

Working with experienced construction partners who understand cost optimization can make a substantial difference. Professional guidance helps identify opportunities for value engineering without compromising quality or functionality. This approach ensures your budget allocates resources efficiently across all project components, from foundation work to finishing touches.

Financing Options and Current Market Conditions

Current warehouse financing rates range from 5.75% to 15.25%, with conventional loans typically falling between 6.10% and 10.75% as of May 2025 [34]. Interest rates are calculated using a benchmark index plus a spread, with the 10-Year Treasury Yield (currently 4.221%) serving as the primary reference for fixed-rate commercial mortgages [34]. The federal funds rate sits at 4.25% to 4.50%, with potential rate cuts projected later in the year [35]. Lenders evaluate multiple risk factors when determining rates, including property type, location, borrower creditworthiness, and loan terms [34]. Fixed-rate commercial mortgages typically price 0.25-0.75% higher than initial variable rates but offer predictable payments, while variable-rate options start lower but carry future payment uncertainty [34]. The commercial lending landscape has shown signs of stabilization in 2024 after significant volatility in 2022-2023, though $210 billion in maturing CMBS loans presents refinancing challenges [34]. Property location significantly impacts rates, with primary markets securing the lowest rates due to perceived lower risk and higher market liquidity [34]. Borrowers can potentially secure more favorable rates by maintaining strong debt service coverage ratios above 1.40x and keeping loan-to-value ratios between 50-60% [34].

Build vs. Buy vs. Lease: A Cost Comparison Analysis

The decision between building, buying, or leasing a warehouse requires careful analysis of financial implications and operational needs. Building a new 10,000-square-foot warehouse typically costs $350,000-500,000 ($35-50 per square foot), with annual operating expenses ranging from $41,320 to $52,640 for utilities, maintenance, and security [36]. Leasing offers greater flexibility with current average rates of $8.22 per square foot monthly ($82,200 for 10,000 square feet), making it ideal for businesses needing adaptability or those with smaller inventories [37]. When comparing ownership options, leasing eliminates substantial upfront infrastructure costs and long-term commitments while providing scalability for seasonal changes and market fluctuations [38]. However, ownership builds equity and offers complete operational control, though it requires significant initial investment and ongoing property tax obligations [38]. For small businesses and startups, leasing provides the most cost-effective entry point with variable pricing based on actual space utilization, versus fixed monthly costs of ownership regardless of usage levels [38]. The outsourcing model has emerged as a particularly flexible option, with costs typically ranging from $10,000 to $200,000 annually depending on storage volume and service requirements - offering significant savings compared to traditional leasing or ownership models [37].

Strategies to Maximize ROI and Minimize Construction Expenses

Maximizing your warehouse investment requires strategic planning from the initial design phase through long-term operations. Smart design choices made early can significantly reduce both construction and operational costs while enhancing functionality. Consider how structural steel frame construction provides the flexibility to accommodate future expansions without major renovations, protecting your initial investment.

Value engineering represents one of the most effective strategies for cost optimization. This process involves analyzing every component and system to identify opportunities for savings without sacrificing performance. For example, optimizing column spacing and roof design can reduce steel requirements by 10-15% while maintaining structural integrity. Similarly, selecting energy-efficient systems may increase upfront costs by 5-8% but typically delivers payback within 3-5 years through reduced utility expenses.

Technology integration should be viewed as an investment rather than an expense. Warehouse management systems, though requiring initial capital outlay, typically reduce operational costs by 20-30% through improved inventory accuracy and labor efficiency. Voice-enabling technology for inventory control and automated climate monitoring systems further enhance ROI by preventing product loss and optimizing energy consumption. Strategic partnerships with experienced contractors who understand these optimization opportunities ensure your project delivers maximum value from day one.

Conclusion

Which construction method best aligns with your warehouse operational needs and budget?

Summary of Key Cost Factors and Considerations

As we've explored throughout this guide, warehouse construction involves multiple cost factors that significantly impact your total investment. The construction method you choose - whether pre-engineered metal buildings, tilt-up, or conventional steel-frame - fundamentally shapes your budget, as detailed in our construction methods analysis. Beyond the initial build costs, your project's success depends on strategic decisions about location, materials, and technology integration.

Key considerations that drive long-term value include selecting the right site near transportation hubs, choosing materials that balance upfront costs with durability, and navigating regional labor markets effectively. The integration of modern technologies like Building Information Modeling (BIM) and automated systems has evolved from optional enhancements to essential investments that deliver measurable returns through improved efficiency and reduced operational costs.

For those considering steel construction solutions, understanding how National Steel Buildings Corp can optimize your investment through pre-engineered systems and expert project management becomes crucial. Our experience shows that successful warehouse projects balance immediate construction costs with long-term operational efficiency, creating facilities that adapt to evolving business needs while maintaining cost-effectiveness throughout their service life.

Making an Informed Warehouse Investment Decision

Making the right warehouse investment decision requires balancing immediate needs with long-term operational goals. As discussed in our market trends section, construction costs have risen significantly, making strategic planning more critical than ever. Your investment strategy should prioritize location selection that optimizes both transportation efficiency and workforce availability - factors that directly impact operational success.

The decision between building, buying, or leasing depends on your specific business model and growth projections. Properties near urban centers and transportation corridors command premium prices but deliver essential advantages for modern distribution operations. Technology integration has shifted from a competitive advantage to a baseline requirement, with automation and IoT systems now fundamental to efficient warehouse operations.

Sustainability features deserve special consideration in your investment planning. Green-certified facilities not only reduce operational costs through energy efficiency but also command higher market values and attract preferential financing terms. As we move through 2024-2025, successful warehouse investments will balance these multiple factors while maintaining the flexibility to adapt to evolving market conditions and customer expectations.

Next Steps in Your Warehouse Construction Journey

Your warehouse construction journey begins with clear objectives and thorough preparation. Define your facility's primary purpose - whether for storage, manufacturing, fulfillment, or multi-purpose operations - as this decision shapes every subsequent choice. Create a comprehensive project roadmap that addresses permitting requirements, zoning compliance, and environmental considerations specific to your location.

Early stakeholder engagement proves invaluable. Consult with operations teams to identify workflow requirements that should influence your design. Plan for technology integration from the start, including warehouse management systems and automation infrastructure, as retrofitting these systems later significantly increases costs and operational disruption.

Establish realistic timelines based on project scope. While smaller facilities may reach completion in 3-6 months, larger distribution centers typically require 9-18 months from groundbreaking to operational readiness. Throughout this process, maintain focus on securing all necessary documentation - from building permits to safety certifications - well before construction begins.

As you move forward, remember that successful warehouse development combines strategic planning with expert execution. Whether you're considering traditional construction methods or exploring modern steel building solutions, partnering with experienced professionals who understand both construction complexities and operational requirements ensures your facility delivers lasting value.

- Warehouse construction costs range from $20-60 per square foot, with pre-engineered metal buildings offering the most cost-effective option at $20-35 per square foot

- E-commerce growth and supply chain disruptions are driving increased warehouse investment, with 56% of companies investing in advanced warehouse technologies

- Regional variations can impact costs by up to 20%, with Pacific Northwest markets commanding premium prices while Sun Belt regions offer better value

- Construction costs have increased 38% since 2019, with material costs rising 2.5 times faster than general inflation

- Location near transportation hubs, though more expensive initially, can reduce operational costs by 20-30% over the facility's lifetime

- Pre-engineered building systems reduce construction time by 30-50% compared to traditional methods

- Site preparation and foundation work typically account for 10-15% of total project costs

- Green-certified warehouses command 19-24% market premiums and reduce operating costs through energy efficiency

- Current financing rates range from 5.75% to 15.25%, with conventional loans typically between 6.10% and 10.75%

- Smart technology integration and automation can reduce operational costs by 20-30% while improving efficiency

- https://blog.unex.com/2024-supply-chain-trends-and-predictions-preparing-your-warehouse-operations-for-the-future

- https://www.shopify.com/enterprise/blog/supply-chain-trends-strategies

- https://interactanalysis.com/insight/warehouse-construction-and-automation-spend-light-at-the-end-of-the-tunnel/

- https://www.deloitte.com/us/en/insights/industry/manufacturing-industrial-products/manufacturing-industry-outlook.html

- https://www.exotec.com/insights/top-warehouse-trends-for-2025/

- https://redstagfulfillment.com/cost-to-build-a-warehouse/

- https://www.cbre.com/insights/reports/warehouse-and-distribution-construction-cost-trends-2023-2024

- https://www.buildingsguide.com/costs/what-does-it-cost-to-build-a-warehouse/?srsltid=AfmBOoqezWFWyoQOlD_jilMdD2d97e92vLGkTnuMFiLngNvOTnoBJxHJ

- https://www.buildingsguide.com/costs/what-does-it-cost-to-build-a-warehouse/?srsltid=AfmBOoqbvqoKoH-uulT-iNhtjuXzgvYAdFWNieIWwXhMj-uyEYALdbos

- https://apxconstructiongroup.com/warehouse-construction-cost/

- https://www.clarisdesignbuild.com/2024-update-commercial-construction-cost-per-square-foot-in-the-us/

- https://hughesmarino.com/blog/2024/09/10/five-important-factors-when-considering-warehouse-site-selection/

- https://www.globaltrademag.com/the-impact-of-real-estate-costs-on-warehouse-location-decisions/

- https://www.steelcobuildings.com/how-much-does-it-cost-to-build-a-warehouse/

- https://www.fcbco.com/blog/warehouse-layout-design-principles

- https://www.procurementresource.com/resource-center/warehouse-factory-unit-construction-cost-price-trends

- https://www.maxxbuilders.com/understanding-warehouse-construction-cost/

- https://www.buildingsguide.com/costs/what-does-it-cost-to-build-a-warehouse/?srsltid=AfmBOopSlLAuJmslXhpyHaTjP7WeFHDfCcwnKH1BYQLsmOpcuqPshdo6

- https://www.steelcobuildings.com/cost-to-build-metal-warehouse/

- https://www.buildingsguide.com/costs/what-does-it-cost-to-build-a-warehouse/?srsltid=AfmBOoqzxVblrowuwmqRV4ZT_9YIefZt7ouCPp91v3IHlxo66-sDu6YL

- https://www.steelcobuildings.com/how-much-does-a-pre-engineered-building-cost/

- https://www.jswonemsme.com/blogs/blogs-articles/pre-engineered-steel-building-systems-vs-conventional-buildings

- https://mbcmusa.com/warehouse-construction-costs-guide/

- https://rothwell-construction.com/tracking-the-evolution-of-warehouse-construction/

- https://www.gep.com/blog/technology/warehouse-automation-roi-comprehensive-analysis

- https://www.sandiego.gov/development-services/permits

- https://www.steelcobuildings.com/how-do-i-get-a-permit-for-my-warehouse/

- https://www.vecnarobotics.com/resources/warehouse-automation-costs/

- https://www.cyngn.com/blog/16-warehouse-automation-trends-for-2024

- https://www.cushmanwakefield.com/en/united-kingdom/news/2024/09/sustainable-warehouses-command-19percent-price-premium

- https://katanamrp.com/blog/green-warehousing/

- https://apxconstructiongroup.com/cost-of-building-a-warehouse/

- https://alansfactoryoutlet.com/blog/warehouse-cost/?srsltid=AfmBOoomsHOA8ZiscsVUqqf-W3sFPOTB5nq_5hSRYhktftto9GdyNolN

- https://stancerealestate.com/commercial-real-estate-interest-rates/

- https://www.commercialrealestate.loans/commercial-mortgage-rates/

- https://alansfactoryoutlet.com/blog/warehouse-cost/?srsltid=AfmBOopLWR4E8LO_WtxTlOsDZtGSQyCZQEmgubKXy7vPkLtA2WCpbCM3

- https://www.warehousingandfulfillment.com/resources/warehousing-services-costs-pricing-rates-and-fees/

- https://eplogistics.com/blog/renting-vs-owning-warehouse-space/

- https://www.autodesk.com/blogs/construction/cost-to-build-a-warehouse/

- https://www.buildingsguide.com/costs/what-does-it-cost-to-build-a-warehouse/?srsltid=AfmBOoqDTPngTSGtPBtNtguNzZ-Kzv3T0L4Tg3jjt6M6oSASEUgjeWjt

- https://www.newblueprintpartners.com/post/manufacturing-vs-warehouse-properties-a-2025-investment-guide

- https://encoradvisors.com/optimizing-warehouse-capacity/

- https://www.nfiindustries.com/about-nfi/insights/prepare-your-warehouse-for-a-dynamic-environment-in-2024/

- https://www.certifyme.net/osha-blog/how-to-build-a-warehouse/

- https://www.waredock.com/magazine/guide-to-warehouse-planning/